Today's KNOWLEDGE Share:

COTTONIZATION: MAKING HEMP AND FLAX FIBERS INTO THE BETTER COTTON

These days it’s hard to imagine that fabrics were ever made out of anything other than cotton or synthetic fibers, yet it wasn’t too long ago that hemp and flax-based fabrics — linen — were the rule rather than the exception. Cotton production has for centuries had the major disadvantages of requiring a lot of water and pesticides, and harvesting the cotton was very labor-intensive, making cotton rather expensive. In order to make separating the cotton fibers from the seed easier, improved versions of the cotton gin (‘cotton engine’) were developed, with the 19th century’s industrial revolution enabling a fully automated version.

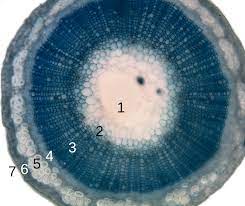

What makes cotton attractive is the ease of processing these fibers, which are part of the seed pod. These fibers are 25 mm – 60 mm long, 12 μm – 45 μm fine fibers that can be pulled off the seeds and spun into yarn or whatever else is needed for the final product, much like wool. Hemp and flax fibers, in contrast, are extracted from the plant stem in the form of bast fibers. Rather than being pure cellulose, these fibers are mostly a mixture of cellulose, lignin, hemicellulose and pectin, which provide the plant with rigidity, but also makes these fibers coarse and stiff.

The main purpose of cottonization is to remove as much of these non-cellulosic components as possible, leaving mostly pure cellulose fibers that not only match the handleability of cotton fibers, but are also generally more durable. Yet cottonization used to be a long and tedious process, which made bast fiber-based textiles expensive. Fortunately, the steam explosion cottonization method that we’ll be looking at here may be one of the methods by which the market will be blown open for these green and durable fibers.

Cotton is somewhat unique in that the plants have always been present in the Old and New World, where civilizations began first using them for fabric many thousands of years ago. Gossypium barbadense was the cotton species domesticated for this purpose in America, and Gossypium herbaceum in Africa and India.

Today, China dominates global production of hemp, and France is the largest producer in Europe. Concerns over the water and pesticide usage involved with cotton production are gradually increasing the need for a cheap way to use bast fibers from hemp and other plants that have a significantly lower environmental footprint.

Source:hackaday.com

Visit MY BLOG http://polymerguru.blogspot.com

#cotton #hemp #flax #naturalfibers #green #greeneconomy #textiles #gossypiumherbaceum

No comments:

Post a Comment