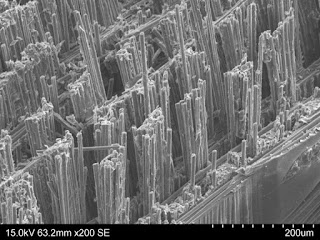

Microscopy Image of carbon fiber

📢Zoom-In Mondays!📢 Have a look at this microscopy! What can you see? What you're looking at is a fracture surface of a carbon fiber composite: one-half of a crack in one of these specimens. This carbon fiber specimen was built up from lots of layers (81 in this case). By making microscopic cuts with a laser, research conducted by J.A Pascoe aimed to figure out how to control crack growth when the specimen was pulled apart. Instead of just fracturing straight through, some bundles of carbon fibers will be pulled out, and stick out relative to the main plane of the crack. Those are the "pillars" that make up the words in the fracture surfaces. By making the right pattern of cuts, the team managed to make the pull-outs happen exactly where they wanted. Source: J.A Pascoe Twitter Profile