Today's KNOWLEDGE Share : Nanostitches

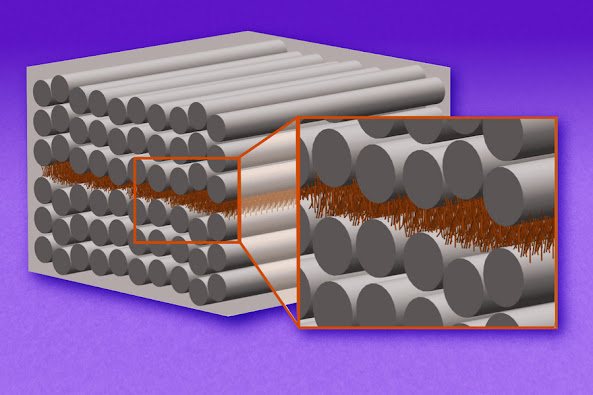

Today's KNOWLEDGE Share “Nanostitches” enable lighter and tougher composite materials In research that may lead to next-generation airplanes and spacecraft, MIT engineers used carbon nanotubes to prevent cracking in multilayered composites. This schematic shows an engineered material with composite layers. Layers of carbon fibers (the long silver tubes) have microscopic forests of carbon nanotubes between them (the array of tiny brown objects). These tiny, densely packed fibers grip and hold the layers together, like ultrastrong Velcro, preventing the layers from peeling or shearing apart. To save on fuel and reduce aircraft emissions, engineers are looking to build lighter, stronger airplanes out of advanced composites. These engineered materials are made from high-performance fibers that are embedded in polymer sheets. The sheets can be stacked and pressed into one multilayered material and made into extremely lightweight and durable structures. But composite materials have one