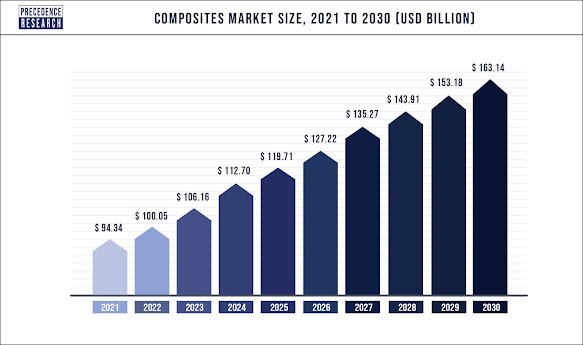

Today's KNOWLEDGE Share:Composites market size

Today's KNOWLEDGE Share The global composites market size is expected to reach around US$ 163.14 billion by 2030! Research conducted by Precedence Research shows that the global composites market size was valued at US$ 94.34 billion in 2021 and is expected to reach around US$ 163.14 billion by 2030, expanding growth at a noteworthy CAGR of 6.3% from 2022 to 2030! Some of the main influencing factors of the composites market include proliferating requirement for lightweight materials in the #defense , #automotive and #aerospace sector, rising demand for chemical and corrosion resistance materials in #pipe & #tank and #construction field. Escalated development of cost effective #carbonfibers , rapid cure #resin system and improved performance glass fiber are some of the evolving trends that are positively affecting #composites market dynamics! Among different product type segmentation, in 2021, #glassfiber appeared as a prominent segment and amounted for around 61.5% re