Today's KNOWLEDGE Share:

The Injection Molder’s Most Important Job

What is the most important job of the injection molder? Ask people in the plastics industry, and you will get a variety of answers.

· Produce parts to the part drawing dimensions.

· Keep the supply chain fed with parts.

· Produce parts at low cost.

· Parts with acceptable cosmetic appearance.

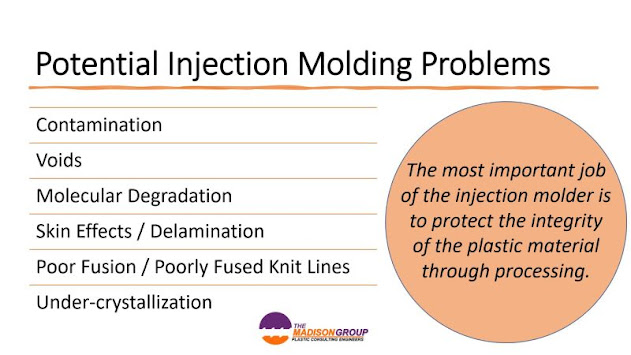

As significant as these functions are, I believe the most important and fundamental role of the injection molder is to protect the integrity of the plastic material. A particular resin was chosen for a part for a reason – because it satisfied the requirements of the application. The injection molding process can have deleterious effects on the properties of the molded part material – mechanical, thermal, chemical, electrical, environmental, and physical.

Injection molding is a very complicated manufacturing process. Some plastics industry leaders suggest forming plastic parts through injection molding is the most difficult of all manufacturing processes, regardless of material.

Think about the complexity of this process. There are so many factors to take into consideration in taking a number of individual solid plastic pellets of comparatively high molecular weight, homogenizing them, getting them to a viscosity low enough to flow through thin runners and gates, and then converting them into a solid of entangled polymer chains. This is not easy. So many things can go wrong when injection molding plastics. In the course of performing thousands of failure analyses, I have seen countless instances where the molder did not sufficiently take care of the resin, which led to premature product failure. Some of the things I have seen go wrong include:

· Contamination

· Voids

· Molecular Degradation

· Skin Effects / Delamination

· Poor Fusion / Poorly Fused Knit Lines

· Under-crystallization

Have I missed any that you have seen?

Remember this: the molder should focus on taking care of the material through processing, regardless whether they are a contract molder or a captive molder.

Source:Jeffrey A. Jansen | The Madison Group

Visit MY BLOG http://polymerguru.blogspot.com

#plastics #plasticsengineering #polymers #manufacturing #materialsscience #injectionmolding #failureanalysis

No comments:

Post a Comment