Today's KNOWLEDGE Share:

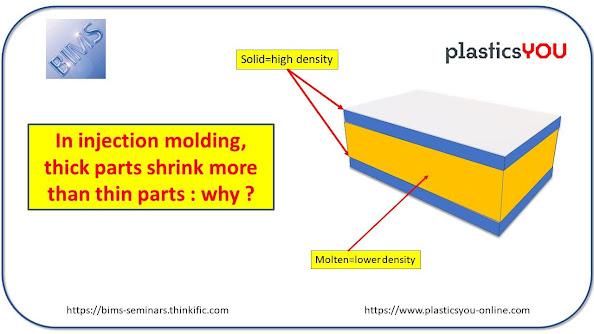

The frozen skin that develops during fill will barely subsequently shrink, since it is already solid !

As a consequence, thin parts, where the frozen skin represents a significant fraction of the thickness, will shrink way less than thick parts where frozen skin is a negligible fraction of total thickness!

Note that since frozen skin is highly fill-rate dependent, when filling slowly you will observe less shrinkage, hence less need for pack.

The IMFLUX process (low pressure molding) does indeed claim essentially no need for a pack.

While this is true, please note that filling as slowly as possible (near 100% frozen skin at end of fill, just before risking a short-shot) means that you will produce VERY ORIENTED plastic parts with :

- very high birefringence (amorphous)

- very anisotropic mechanical properties (semi-crystalline).

Many technical parts would rather benefit from low molecular orientation and maximum isotropy of performance, hence a faster fill followed by the appropriate packing is often a better choice.

source:VITO LEO

Visit MY BLOG http://polymerguru.blogspot.com

#injectionmolding #injectionmoldingmachine #frozenskin

#fillrate #shrinkage

No comments:

Post a Comment