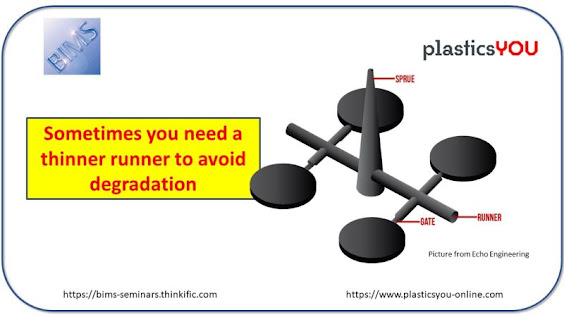

Today's KNOWLEDGE Share:

THIN RUNNER

I am saying that sometimes, you will avoid thermal degradation in runners by going thinner !

How is that possible ?

Materials like RPVC have a strong tendency to degrade in extrusion and even more in Injection Molding. Some lubricants are typically present in the compounds to promote the slip of the melt on the reciprocating screw surfaces.

Such slip will also be present in runners, in particular in hot runners (considered as a dangerous option in PVC molding by most).

Slip is very well described by a power law relating Slip Velocity to the applied Shear Stress.

So the onset of slip is triggered by a sufficiently high stress, very much like motion is triggered in a static friction coefficient context.

This means that in a larger runner, where Shear Stress is much lower, the melt may well NOT slip, resulting in a very long (infinite) residence time of the top melt layers in contact with the hot runner chamber.

By making your hot runners thinner, you increase stress and thus promote slip and consequently lower the melt residence time and the associated risk of thermal degradation.

Years ago, we took advantage of Flow Analysis (with a Slip model included in the constitutive laws) and the above idea to design a hot runner system for PVC that proved to work for weeks without any melt degradation.

This may not apply to many other materials and will not be very relevant in cold runners where residence time will never exceed cycle-time, but I thought it was good food for thought anyway. It could apply to the nozzle of a molding machine by the way.

Source:VITO LEO

Visit MY BLOG http://polymerguru.blogspot.com

#plastics #polymers #injectionmolding #thermal #extrusion #shear #hotrunner #meltflow #meltdegradation #PVCmolding # #design

No comments:

Post a Comment