Today's KNOWLEDGE Share

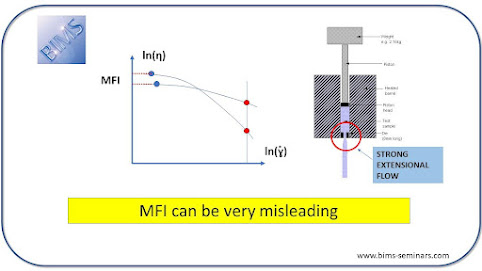

Be very cautious when using Melt Flow Index for material comparison in Injection Molding.

MFI is actually measuring a very low shear-rate viscosity and when comparing two materials, you are not even comparing at same shear-rate (the test is constant load based). If shear-thinning is very different, moldability may be completely off from apparent MFI related conclusions (see picture).

The normalized very short dies used for MFI also lead to a very significant contribution of extensional viscosity to MFI values, which doesn't really help either...

When it comes to Injection Molding, make sure you have a comprehensive set of data describing shear viscosity vs. shear-rate and temperature. Entrance effects in capillary tests may also inform you about extensional viscosity importance.

Source:Vito leo

Follow: http://polymerguru.blogspot.com

#plastics #injectionmolding #plasticindustry #sherarviscosity #meltflowindex

No comments:

Post a Comment