Evonik is introducing a new #carbonfiber reinforced #PEEKfilament, for use in 3D printed medical implants.

This smart biomaterial can be processed in common extrusion-based 3D printing technologies such as #fusedfilamentfabrication (FFF). The specialty chemicals company will present the new product for the first time at coming next medical technology and #3Dprinting related trade shows.

High Bio-compatibility for Metal Allergy-patients:

Dubbed VESTAKEEP® iC4612 3DF and VESTAKEEP® iC4620 3DF, the two available filaments feature 12% and 20% carbon fiber content, respectively. The two grades offer a choice of material depending on the required strength and flex properties of 3D printed implants such as #bone plates and other reconstructive #prostheses.

Evonik’s VESTAKEEP® iC4612 3DF and VESTAKEEP® iC4620 3DF offer great benefits from the strength from the high carbon-fiber content, matched with the #ductility of its PEEK component. Additional product benefits include the ability to define the alignment of the carbon fibers during the 3D printing process, high bio-compatibility for metal allergy-patients, and the no x-rays artifacts.

“By introducing the world’s first carbon-fiber reinforced PEEK filament for long-term #medicalimplants, we continue to design biomaterials that open up new possibilities in today’s medical technology for patient-specific treatment,” says Marc Knebel, head of Medical Systems at #Evonik. “As passionate experts with decades of experience in polymer chemistry, we combine a unique set of competencies in materials science, manufacturing technologies and regulatory expertise to customers to accelerate time-to-market of new medical technologies for people's lives beyond limits.”

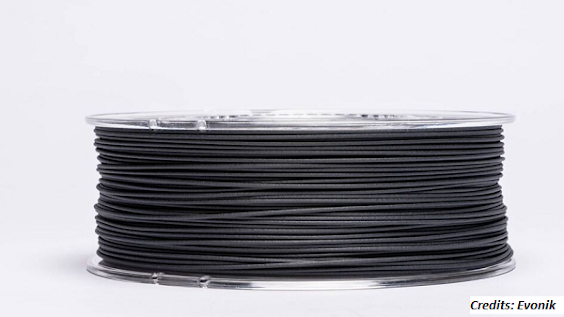

With a diameter of 1.75 mm, VESTAKEEP® iC4612 3DF and VESTAKEEP® iC4620 3DF are supplied on 500g and 1,000g spools that can be used directly in standard FFF/FDM 3D printers for PEEK materials. The filament is subjected to strict quality management for medical materials.

Grades for Short-term as well as Long-term Body Contact Applications:

Over the last five years, Evonik has been gradually developing new PEEK-based filaments for medical 3D printing applications and thus setting material quality standards in medical technology with #additivemanufacturing. The current portfolio includes different grades for long-term and short-term body contact applications:

Long-term body contact applications:

VESTAKEEP® i4 3DF – Implant grade (long-term)

VESTAKEEP® i4 3DF-T – Test and development grade

VESTAKEEP® iC4800 3DF – Osteoconductive implant grade

VESTAKEEP® iC4612 3DF – Carbon-fiber reinforced (12%) implant grade

VESTAKEEP® iC4620 3DF – Carbon-fiber reinforced (20%) implant grade

Short-term body contact applications:

VESTAKEEP® Care M40 3DF - Medical care grade

Source: Evonik/specialchem.com

Follow: http://polymerguru.blogspot.com

No comments:

Post a Comment