Today's KNOWLEDGE Share:

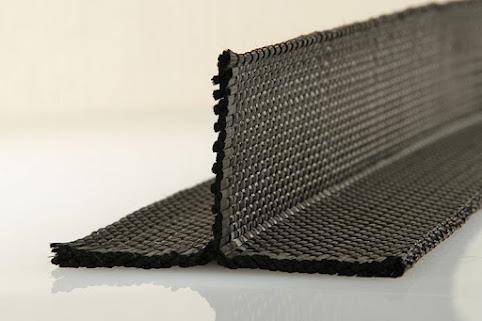

Carbon fiber 3D woven joints

3D woven joints and preforms are widely used in aircraft, missiles, satellites, spacecraft, helicopters, vehicles and more. By means of the low cost, fast production and lightweight solutions, 3D woven carbon fiber composites are the products of the present and the future!

What are the advantages of using 3D woven composites, instead of common 2D laminated composites?

- They can be directly woven into complex net shapes

- Allows higher fiber volume

- Improved impact resistance and Compression After Impact

- Yarns can be controlled according to stability, strength and shape desired in the end product

- Possibility to choose different fiber types such as carbon fiber, aramid, glass etc. in the weaving process

- Practically zero delamination between the layers

- Reduce the cost of composite parts production

Source: Erginer Ceramic and Composites Technology/# managingcomposites

No comments:

Post a Comment