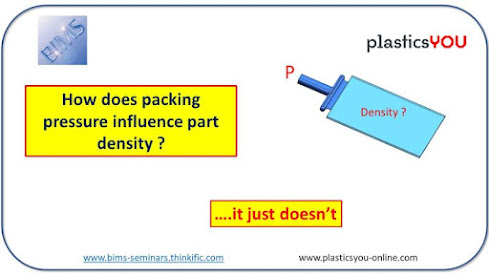

Today's KNOWLEDGE Share:Packing Pressure:

Today's KNOWLEDGE Share: Packing Pressure: The final (true not apparent) density of a molded polymer is not packing pressure dependent. Your packing pressure will allow you to compensate for shrinkage by compressing the melt in the cavity. As a transient, you will indeed increase the melt density as you pack. But at the end of the process, after ejection and cooling, the part density will be controlled by the polymer thermodynamics, not by the process. So packing will change the part volume, the weight, the thickness along the flow, and dimensions in general, but not the material density. Well, to be very precise, in crystalline materials pressure may influence crystallization (one way or the other in fact) leading to relatively small density variations. But if we look at amorphous materials for the sake of simplicity, disregarding voids and associated apparent density, the actual material density will be the same near or far from the gate, with a lot or very little packing ! Sourc