Using ultrasonic waves that propel drug molecules into the skin, the patch could be used to treat a variety of skin conditions.

The skin is an appealing route for drug delivery because it allows drugs to go directly to the site where they’re needed, which could be useful for wound healing, pain relief, or other medical and cosmetic applications. However, delivering drugs through the skin is difficult because the tough outer layer of the skin prevents most small molecules from passing through it.

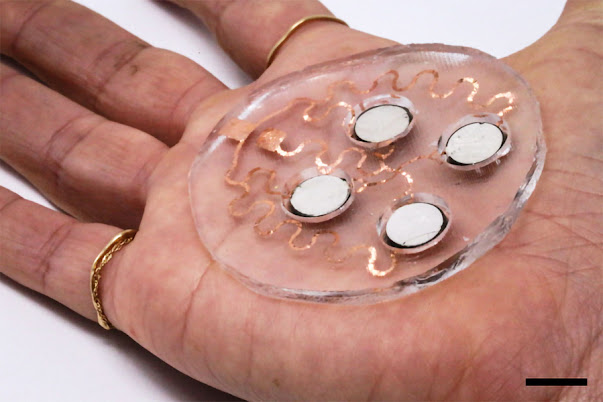

In hopes of making it easier to deliver drugs through the skin, MIT researchers have developed a wearable patch that applies painless ultrasonic waves to the skin, creating tiny channels that drugs can pass through. This approach could lend itself to delivery of treatments for a variety of skin conditions, and could also be adapted to deliver hormones, muscle relaxants, and other drugs, the researchers say.

“The ease-of-use and high-repeatability offered by this system provides a game-changing alternative to patients and consumers suffering from skin conditions and premature skin aging,” says Canan Dagdeviren, an associate professor in MIT’s Media Lab and the senior author of the study. “Delivering drugs this way could offer less systemic toxicity and is more local, comfortable, and controllable.”

MIT research assistants Chia-Chen Yu and Aastha Shah are the lead authors of the paper, which appears in Advanced Materials, as part of the journal’s “Rising Stars” series, which showcases the outstanding work of researchers in the early stages of their independent careers.

A boost from sound waves

The researchers began this project as an exploration of alternative ways to deliver drugs. Most drugs are delivered orally or intravenously, but the skin is a route that could offer much more targeted drug delivery for certain applications.

“The main benefit with skin is that you bypass the whole gastrointestinal tract. With oral delivery, you have to deliver a much larger dose in order to account for the loss that you would have in the gastric system,”

Ultrasound exposure has been shown to enhance the skin’s permeability to small-molecule drugs, but most of the existing techniques for performing this kind of drug delivery require bulky equipment. The MIT team wanted to come up with a way to perform this kind of transdermal drug delivery with a lightweight, wearable patch, which could make it easier to use for a variety of applications.

The device that they designed consists of a patch embedded with several disc-shaped piezoelectric transducers, which can convert electric currents into mechanical energy. Each disc is embedded in a polymeric cavity that contains the drug molecules dissolved in a liquid solution. When an electric current is applied to the piezoelectric elements, they generate pressure waves in the fluid, creating bubbles that burst against the skin. These bursting bubbles produce microjets of fluid that can penetrate through the skin’s tough outer layer, the stratum corneum.

“This works open the door to using vibrations to enhance drug delivery. There are several parameters that result in generation of different kinds of waveform patterns. Both mechanical and biological aspects of drug delivery can be improved by this new toolset.

Source:MIT NEWS OFFICE

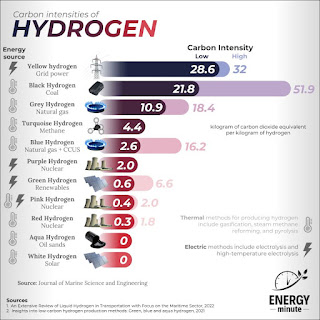

Low carbon hydrogen from water electrolysis using renewable power:green

Low carbon #hydrogen from water electrolysis using nuclear power: pink

Low carbon hydrogen from natural gas using reforming with #CCS: blue

Low carbon hydrogen from coal #gasification with CCS: purple

Low carbon hydrogen from #naturalgas pyrolysis and solid carbon production: turquoise