Today's KNOWLEDGE Share: METHANOL

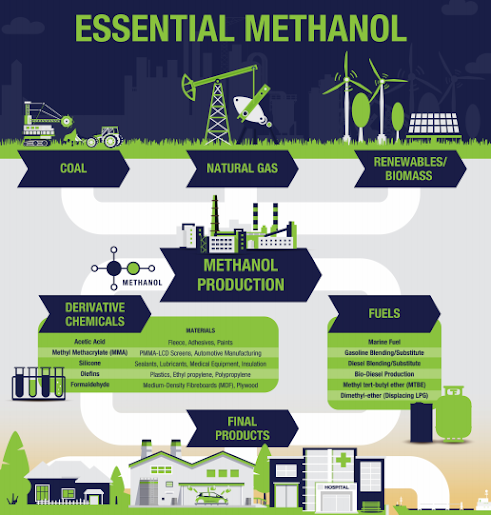

Today's KNOWLEDGE Share: METHANOL Methanol occupies a critical position in the chemical industry as a highly versatile building block for the manufacture of countless everyday products such as paints, carpeting, plastics, and more. Increasingly, methanol is being employed around the globe in many innovative applications to meet our growing energy demand. We use methanol to fuel our cars and trucks, marine vessels, boilers, cookstoves, and kilns, among an increasing list of market applications. Methanol is a highly versatile product that finds itself in many ubiquitous household products, essential components for cars, and the production of other valuable chemicals. Methanol’s versatility lies in its ability to be produced from different feedstocks – from natural gas, waste, and captured CO2 combined with green hydrogen. Increasingly, methanol is considered a clean and sustainable fuel rather than just a petrochemical. Its inherent clean-burning properties produce lower emissions (w