Today's KNOWLEDGE Share:

Strength of fibers

Fibers generally exhibit much higher strengths than the bulk form of the same material. The probability of a flaw per unit length present in a sample is an inverse function of the volume of the material. Since fibers have a very low volume per unit length, they are much stronger on average than the bulk material, which has a high volume per unit length. On the other hand, because a bulk material has a much higher content of weakening flaws, it exhibits much lower variability in strength. Thus, the smaller the fiber diameter and the shorter its length, the higher the average and maximum strength but the greater the variability. Therefore, fibers have higher strength than their bulk counterparts, but they have greater scatter in their strength. The variability in the strength of fibers is a function of the flaws they contain and, in particular, the flaws they contain on the surface.

Flaws can be minimized by careful manufacturing processes and the application of coatings to protect them from mechanical and environmental damage. Precursors used in fiber manufacturing processes must be of high purity and free of inclusions. Many fiber manufacturing processes involve drawing or spinning operations that impose very high degrees of orientation parallel to the fiber axis, thus producing a more favorable orientation in the crystalline or atomic structure. In addition, some processes involve very high cooling rates that produce ultrafine-grained structures, which are not achievable in most bulk materials.

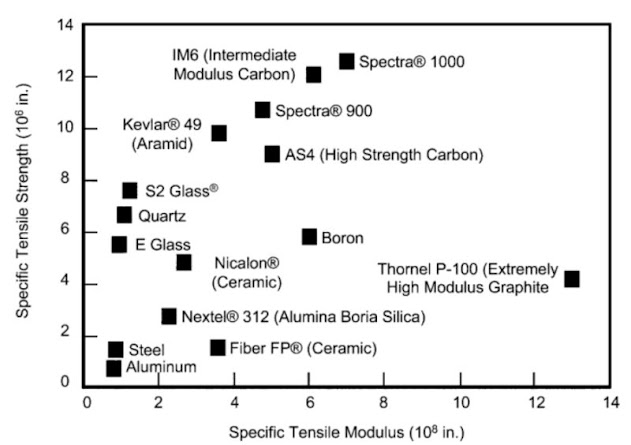

That said, how do commercially important fibers fair against each other when it comes to specific strength and specific modulus? Check out this graph to discover!

Bibliographical Reference:

Structural Composite Materials - Page 32

Source:#managingcomposites #thenativelab

Visit MY BLOG http://polymerguru.blogspot.com

#fibers #strength #mechanical #composites #manufacturing

No comments:

Post a Comment