Researchers Identify Latex Proteins to Enhance Natural Rubber Production

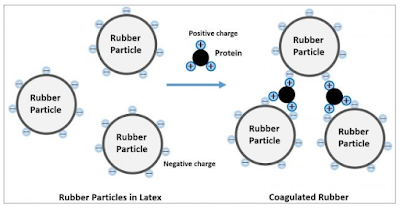

The Yokohama Rubber Co., Ltd., has announced that the results of joint research projects conducted since 2013 with two universities in Thailand, a major producer of natural rubber, were recently presented at The International Polymer Conference of Thailand 2018 (PCT-8). The joint research projects were conducted with researchers at Mahidol University and Prince of Songkla University. The research with Mahidol University succeeded in analyzing proteins contained in sap (latex), the base raw material for natural rubber, and identifying the proteins deeply involved in natural rubber biosynthesis. The research deepens the understanding of the biosynthesis of natural rubber, making it possible to accelerate research related to quality and production. Evaluating Physical and Chemical Properties of Rubber The research conducted at Mahidol University entailed the extraction and nano-level analysis of proteins from fresh latex and seedlings from Para rubber trees. The anal