Today's KNOWLEDGE Share

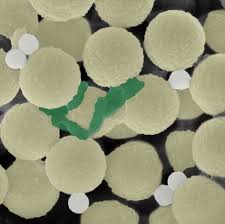

Some molding compounds contain a so-called "external lubricant". It is essentially a second immiscible polymeric material with a much lower viscosity.

What happens when you mold such materials ?

In extrusion things are quite obvious. The hydrodynamic forces push the dispersed lubricant to the surface of the die where they can act as expected and promote slip of the major phase polymer.

In Injection Molding the combination of the Fountain flow, moving inner flow layers to the very edge, and the presence of a frozen skin, create a more complex situation.

The high shear layer where lubricant will accumulate is INSIDE the frozen skin ! While this can still help to reduce the pressure to fill, this situation will also induce a serious risk of blistering/delamination.

This delamination was well known for instance in the Xenoy grade made of PC/PBT. But other compounds, containing for instance a silicon based lubricant, will produce the same result, as reported by some of my customers.

So, keep in mind that the lubricant (possibly necessary at the outer surface of the molded part if the intention is to control friction coefficient) doesn't quite go where you'd hope to see it.

Note that this delamination can also occasionally be observed in pure HDPE if the molecular weight is high enough. In this case the low molecular tail (waxes) will accumulate at the frozen skin interface, promoting delamination.

Source:Vito Leo

#injectionmolding #plastics #lubricant