Today's KNOWLEDGE Share

Toray Developed Glass Fiber Reinforced PPS Recycling Technology

-Established New Technology which matches initial performance with virgin material and reduces CO2 emission -

Toray Industries, Inc., announced today that it has developed a technology that makes it possible to recycle glass fiber-reinforced #polyphenylenesulfide (PPS-GFRP) whose performance matches initial performance of virgin resins. By Increasing recycling ratio of PPS GFRP, it will contribute to reducing #CO2emission.

PPS resin is an #engineering plastic with excellent #heatresistance and chemical resistance. More than 90% of PPS resin is glass fiber reinforced and applied for various types of industrial applications. Also, PPS resin has excellent insulation resistance. It is applied for #electronicparts such as #semiconductors and #EVparts. Demand of PPS resin is expected to increase along with these applications and the need of PPS recycling reins.

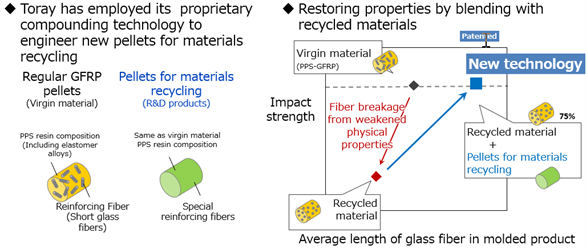

The conventional process for recycling PPS-GFRP shortens #glassfibers and break them. This significantly decreases mechanical strength. To meet the performance requirements of resin molded products, manufacturers generally apply them in applications with lower quality requirements. This makes it difficult to increase the #recycling ratio of PPS resin.

Toray developed pellets for recycling materials by leveraging proprietary compounding technology to blend PPS resin with special #reinforcingfibers. Blending these pellets with recycled material makes it possible to maintain comparable performance with virgin material and can be applied to same application, such as horizontal recycling and expected to be used for various applications.

This technology can deliver comparable mechanical strength with injection grade moldings wholly made with virgin material. This is even when recycled material accounts for 50% or more of the #PPS-GFRP. Another benefit of 50% recycled content is that it reduces CO2 emission by at least 40%.

The company is working on technologies to broaden variations by designing different resins and additives in pellets for recycling materials. It looks to supply recycled PPS-GFRP pellets after engineering optimal pellet blend ratios and formulations that meet customer demand requirements and by drawing on Materials Informatics-based prediction technologies.

Collaborating with several molding companies and other business partners, Toray has already embarked on closed recycling initiatives with its technology. One move has been to supply customers with recycled PPS-GFRP pellets blended with those for materials recycling based on process remnants from customer plants. The company is also conducting tests to verify horizontal recycling and prepare for commercialization with cooperations from customers.

Source:Toray

Follow: http://polymerguru.blogspot.com