Today's KNOWLEDGE Share

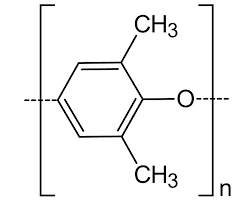

Key features of PPE and modified PPE resins

Heat resistance:

Pure PPE resin has a glass transition point of approximately 210°C. Modified PPE resins exhibit a range of behavior depending on the partner material used to form the alloy: from high-fluidity grades with heat deflection temperatures below 100°C to highly heat-resistant grades with heat deflection temperatures above 200°C.

• Flame retardance:

The oxygen index (a measure of the quantity of oxygen needed for combustion) for pure PPE resin is 28, a high value indicating that it is relatively easy to make this material flame-retardant. Asahi Kasei's lineup of modified PPE resins includes several grades with excellent flame retardance at the UL94 V-0 level.

• Low specific gravity:

PPE resin is a lightweight material whose specific gravity just 1.06—is the lowest of all engineering plastics.

• Electrical insulation:

PPE resins have high volumetric resistivity, making these materials excellent electrical insulators. The outstanding tracking resistance and other favorable electrical properties of PPE resins make these materials a common choice for a wide variety of products.

• Low water absorption:

Pure PPE resin is a low-water-absorption material. Modified PPE resins retain this advantage, exhibiting minimal change in physical properties and minimal dimensional variation upon water absorption.

• Hydrolysis resistance:

Modified PPE resins boast excellent heat resistance, and the absence of esters or amides from their chemical structures also ensures excellent resistance to warm water and to hydrolysis.

• Resistance to acids and alkalis:

A characteristic feature of modified PPE resins is their strong resistance to acids and alkalis.

• Low dielectric permittivity and low dielectric loss tangent:

PPE resin exhibits low dielectric permittivity and low dielectric loss tangent over a wide range of frequencies and these properties remain largely unchanged across variations in operating temperature and humidity. The low transmission losses achievable with modified PPE resins make these materials a common choice for components of information and communication systems.

• Low linear-expansion coefficient:

PPE resin exhibits the lowest linear-expansion coefficient of all engineering plastics, minimizing shrinkage during molding and ensuring excellent dimensional stability and dimensional precision.

source:Asahi Kasei