Today's KNOWLEDGE Share:

METHANOL

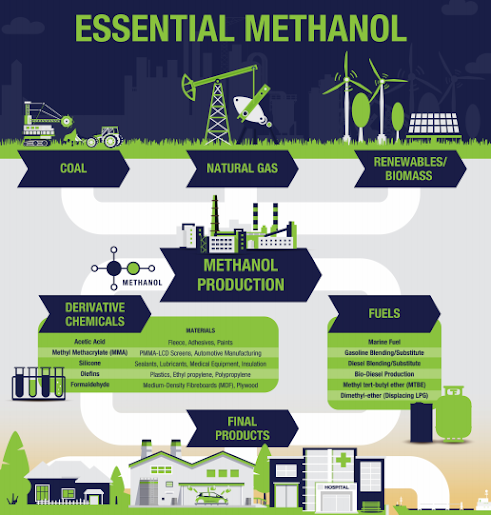

Methanol occupies a critical position in the chemical industry as a highly versatile building block for the manufacture of countless everyday products such as paints, carpeting, plastics, and more.

Increasingly, methanol is being employed around the globe in many innovative applications to meet our growing energy demand. We use methanol to fuel our cars and trucks, marine vessels, boilers, cookstoves, and kilns, among an increasing list of market applications.

Methanol is a highly versatile product that finds itself in many ubiquitous household products, essential components for cars, and the production of other valuable chemicals. Methanol’s versatility lies in its ability to be produced from different feedstocks – from natural gas, waste, and captured CO2 combined with green hydrogen. Increasingly, methanol is considered a clean and sustainable fuel rather than just a petrochemical. Its inherent clean-burning properties produce lower emissions (while improving fuel efficiency) upon land/marine vehicle combustion. When made from renewable feedstocks like captured CO2 or waste, methanol becomes a net carbon-neutral fuel aligned with climate change policies to lower greenhouse gas emissions.

Renewable Methanol:

Compared to conventional fuels, renewable methanol cuts carbon dioxide emissions by up to 95%, reduces nitrogen oxide emissions by up to 80%, and completely eliminates sulfur oxide and particulate matter emissions.

Methanol (CH3OH) is a liquid chemical used in thousands of everyday products, including plastics, paints, cosmetics and fuels. Liquid methanol is made from synthesis gas, a mix of hydrogen, carbon dioxide and carbon monoxide. These simple ingredients can be sourced from a wide range of feedstocks and using different technology approaches.

Renewable methanol is an ultra-low carbon chemical produced from sustainable biomass, often called bio-methanol, or from carbon dioxide and hydrogen produced from renewable electricity.

The Methanol Institute (MI) is tracking more than 80 renewable methanol projects around the globe that are projected to produce more than eight million metric tons (2.7 billion gallons or 10 billion liters) per year of e-methanol and bio-methanol by 2027.

Methanol is an essential chemical building block and emerging energy resource. Methanol is synthesized using a mixture of hydrogen, carbon dioxide, and carbon monoxide. These elements can be derived from a variety of feedstocks and processes, with conventional methanol produced from natural gas or coal. Renewable methanol is a low carbon and net carbon neutral liquid chemical and fuel produced from sustainable biomass, often called bio-methanol, or from captured carbon dioxide and hydrogen produced from renewable electricity, referred to as e-methanol.

Source:Methanol Institute

Visit MY BLOG http://polymerguru.blogspot.com

#methanol #renewableenergy # #carbonneutral #alternativeenergy #sustainable #marine