Today's KNOWLEDGE Share:

COMPRESSION LOADING in Plastics

Compression is the application of a load on opposite surfaces of a structure to cause crushing. In reality, plastics rarely show catastrophic cracking in compression. However, failure may be classified by the degree of distortion from the original shape due to the compressive stress.

This type of failure is commonly seen as:

· Creep when the component distorts and takes a permanent set, such as the flattening of an appliance caster.

· Stress Relaxation when the component loses inference with a mating part, such as a gasket.

A notable exception here are thermoset plastics, which can shatter in compression, and often demonstrate true compressive rupture failure.

More commonly, plastics will continue to compress to a flat disk as the applied stress increases, without fracture. In many instances, the application of compressive loading results in deformation of the part, such as buckling or bending, producing corresponding tensile loads at other locations.

The common responses to compressive loading are:

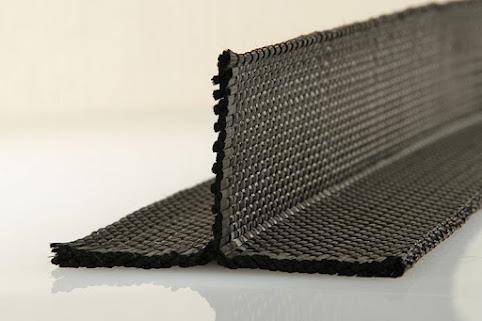

· Buckling

· Shearing

· Double barreling

· Barreling

· Homogeneous compression

· Instability

Compression of plastics is tested per ASTM D 695. As per the standard, a specimen is placed between two parallel plates on a universal testing machine (UTM). Load is applied in order to move the plates together at a specified rate. The load cell records compressive stress, while displacement is measured from crosshead movement. The test results in a plot of stress versus strain.

The compressive strength of a material is the force per unit area that it can withstand in compression. Plastic resin suppliers generally report compressive yield strength, the stress measured at the point of permanent yield, zero slope, on the stress-strain curve. The analogous test to measure compressive strength in the ISO system is ISO 604.

Typically, the compressive modulus and yield stress are usually greater than the corresponding tensile values.

Source:Jeffrey A. Jansen