Do we need to depend on Lithium-ion batteries for Electric vehicles for a decade or more?

Climate changes have happened rapidly throughout many regions in the recent decade. On one side the deforestation takes place steadily in many regions and the natural resources are draining out a lot. Each country is losing its share of forest land every year drastically.

On the other side, the sudden interest among Electric vehicle manufacturers made the world depend on lithium-ion batteries more than expected a decade ago.

Some EV manufacturers are holding licenses for such minerals in the US for the lithium extraction for the Lithium Iron Phosphate battery cells. The world needs many materials for the production of an EV battery. Mining and deforestation happen at the same time everywhere that is not safe for the environment that we humans aim to create for future generations.

Mining at depth will make the earth weakening as well as the water gets toxic too. Toxic rain will be the result.

Don't we have any other alternative?

Magnesium-based and sodium ion-based batteries the EV manufacturers can aim for the progress in that line.

Mining project numbers are increasing and the largest corporations aiming to mint the money in the name of an alternate vehicle market. There is a strict and combined regulation the Energy associations must create as early as possible to avoid the blame game of each technology.

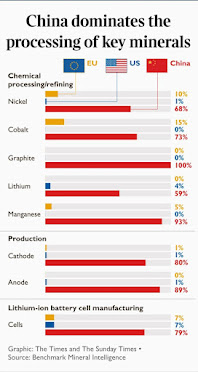

The more we destroy our soil and trees, the more we get unhealthy in the coming days, which is not a good sign for a healthy environment. We should not switch all of a sudden on one technology that seems to create more pain for humans in the days to come. China is supplying most of the minerals to the EV battery manufacturers today and the country is losing its beauty so we shouldn't forget it.

Despite depending on Electric vehicles, it is time to invest in more sustainable projects such as Green Hydrogen/Solid Hydrogen/Green Ammonia/LNG/Methanol, etc for a better alternate fuel market.

It is time to think about our future than the present comfortable life.

Let's hear the workable road map on this topic. Share your comments if possible so that we can make a better world for sure.

Muthuramalingam Krishnan