Today's KNOWLEDGE Share

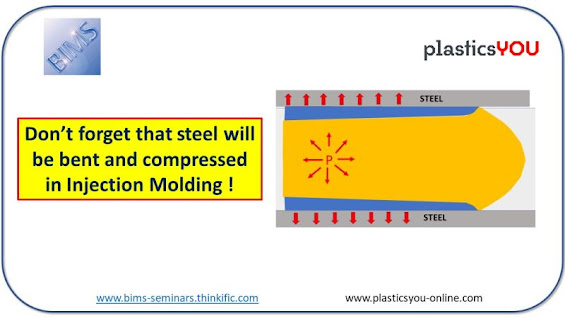

Based on consulting requests, I realize that a lot of people forget that huge forces are developed during the molding process, as a result of pressure levels exceeding often 1000 bar/100MPa.

That amounts to 1 metric Ton of equivalent force applied to each square cm of tool surface.

That is why clamp tonnage numbers are what they are of course.

But, no matter how good your steel or tool design is, metal will bend significantly when subjected to huge unbalanced forces.

And, even more surprisingly, for balanced forces, the cavity will expand by "compressing" the steel by quite a few microns !

You can run a quick FEA to check that, by applying 1000-2000 bar on a piece of steel.

Of course tubular shaped parts will readily see significant core shift problems as soon as flow is slightly unbalanced, since a differential of a few Tons-force can quickly appear if flow is not perfectly balanced. The problem here is, of course, that the more the core deflects, the more the unbalance grows. So it is a bad case of positive feedback leading to catastrophic results (unexpected weldlines in the thinned side towards which the core has been bent/pushed).

Don't underestimate the importance of these effects in molding.

While coupling Flow Analysis with stress analysis on the steel structure can supposedly model this, it is very challenging to describe the complex tool assembly. And such coupled approaches can be very challenging numerically. So, while core-shifting predictions are now quite standard, full tool deflections are usually neglected in simulations. And the clear tendency of steel compressibility to lead to overpack is never accounted for.

Source:Vito Leo

#injectionmoulding #polymers

No comments:

Post a Comment