Today's KNOWLEDGE Share

Ever wondered why fibers in GF filled materials always end up with an L/D of about 20 ?

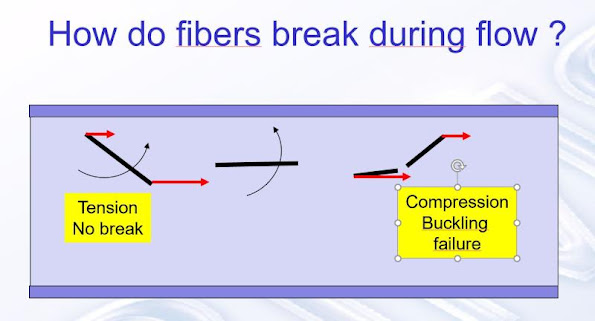

If you consider a diluted case (to avoid fiber-fiber damage), and also forget for a moment the fibers pinned in the frozen skin that could snap in bending mode, you are left with the effect of flow shear stress on fiber damage.

And it turns out that fiber rotation due to shear produces a cyclic switch from tension to compression as shown in the picture. While the tension will never do any harm to the glass fiber (far too low), the compression load will trigger buckling and will snap the fibers just like you can snap raw spaghetti between your fingers ! At L/D=20 the buckling load threshold is so high that damage by flow becomes unlikely.

Source:Vito leo

Follow: http://polymerguru.blogspot.com

#plastics #glassfiber #injectionmolding #compression #fiberdamage

No comments:

Post a Comment