Today's KNOWLEDGE Share

Do you really understand how important mold temperature is in Injection Molding ?

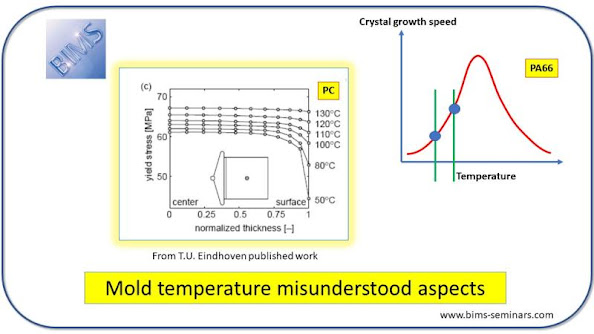

When molding semi-crystalline materials, a higher mold temperature will accelerate crystallization and possibly reduce (Yes, REDUCE) cycle time (see top right kinetic curve), while producing a stiffer part.

When molding amorphous polymers, the degree of Physical Aging induced by a higher mold temperature will lead to a higher Yield Stress (left graph) and serious consequences on mechanical response. Creep performance and Impact will change by orders of magnitude, in opposite directions.

Many erroneously interpret these effects as being due to residual stresses.

Source:Vito Leo

Visit MY BLOG http://polymerguru.blogspot.com

#plastics #injectionmolding #polymerscience #molding #temperature

No comments:

Post a Comment