Today's KNOWLEDGE Share:

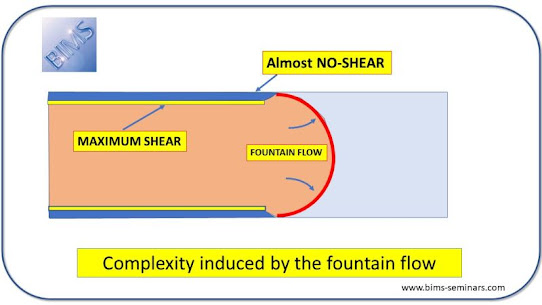

Why is the maximum shear recorded somewhat inside the skin of molded parts ?

Fountain flow brings the material on the walls "sideways". So, the very top skin of a molded specimen is not very oriented at all. Inside the frozen skin (a time/position dependent "moving boundary" line) we get maximum shear and corresponding higher molecular orientation.

The "yellow layer" depicted can often be responsible for delaminations of molded parts, since high shear could expel low molecular fractions or lubricants which accumulate under the first formed skin.

Low viscosity fractions will naturally move (hydrodynamic forces) to the highest shear-stress regions to minimize total flow energy.

Extreme levels of orientation also freeze the material in a lower entanglement state, which can somewhat compromise the interlayer integrity in the thickness direction while boosting in-flow performance.

Source:Vito Leo

Visit MY BLOG http://polymerguru.blogspot.com

#polymers #plasticsindustry #injectionmolding #shear #materialsscience #freeze #friction #flow

No comments:

Post a Comment