Compared to conventional plastics, the new material has an excellent heat resistance with the longest flame blocking duration in the world.

In-house test results show that the material prevented flame propagation for over 400 seconds above 1,000 degrees

Helps secure the time required for evacuating drivers and suppressing fire.

The mass-production system is fully established, beginning a full-scale production starting 2023

The material will be applied to various industries based on the supply of battery pack covers

Steven Kim (Senior VicePresident/ Division Leader, Engineering Materials Division. Advanced Materials),“Continued research for over a decade to solve our customer’s pain points have turned out to be tremendously meaningful.”

“Based on the world’s best compounding technology, LG Chem plans to continue its R&D and invest in mass production to lead a fast-growing e-Mobility market.”

LG Chem plans to target the market with its recent development of battery pack plastic materials that can delay the thermal runaway of electric vehicle batteries for the longest period in the world.

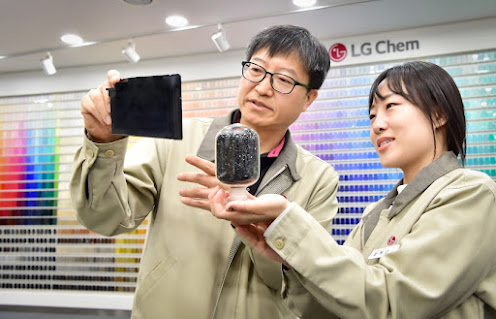

With its own technology and manufacturing methods, LG Chem announced that it developed flame-retardant engineering plastic material that prevents deformation by heat.

Thermal runaway, the main cause of fire in electric vehicle batteries, is a phenomenon where battery cell suffers stresses from various origins and heats up subsequently. Flames arise once the battery’s internal temperature rises above a certain level due to short circuits such as overvoltage and over-discharge. The lithium-ion battery has high reactivity to water, which makes it difficult to extinguish it with water in case of fire.

LG Chem’s newly developed special flame retardant is a high-functional engineering plastic material that consists of various material groups such as polyphenylene oxide (PPO), polyamide (PA), and polybutylene terephthalate (PBT).

Compared to general flame-retardant plastics, the new material can block heat for a longer period when it is applied to an electric vehicle’s battery pack cover thanks to its excellent heat resistance. The material also has superb dimensional stability that can continue to maintain its shape despite temperature changes. According to LG Chem’s in-house test results, the material can block flame propagation caused by thermal runaway for more than 400 seconds at 1,000 degrees. This is 45 times better than general flame-retardant plastics.

LG Chem’s new engineering plastic material can be applied to battery pack covers so that it can delay the combustion period in case of fire and prevent the flame from spreading. This will help secure the time needed to evacuate drivers and put out a fire.

Source: LG CHEM

No comments:

Post a Comment