📣Composites Showcase!📣

Let's learn more about the introduction of composite materials in tennis racquets!

For many years, tennis was played with wooden rackets. There was some experimentation with laminating woods, but Bill Severa, Wilson’s global director of technology says the wood rackets remained pretty much the same from the early teens [in the 20th century] up until the mid-60s.

"The wood rackets were all based off natural wood and while we sold millions and millions of rackets in those years, there was no real definite evolution," he says.

That evolution took public shape in 1967. But it started in 1953, when Frenchman René Lacoste came up with a design for a metal racket, patenting it that same year. Wilson later acquired the rights to it and in 1967, players grew intrigued enough by the Wilson-made T2000 that it showed up in tournaments. It made its first appearance in the Wilson catalog in 1969.

And with wood finding a challenger in steel, the race for new materials was on. Aluminum, easier to mold than steel, made its debut in the 1970s. But there was more coming. The carbon fiber composite industry wasn’t new in the '80s, having been around since the '50s, Severa says. But at exorbitant prices, carbon fiber wasn’t plausible for sporting goods. As prices started to drop for carbon fiber, tennis companies could experiment.

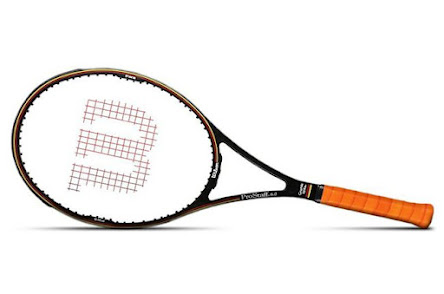

The big convergence was in 1983 when the last Wilson catalog featured wood, steel, and composite rackets. Just one year later, the company that had been making wood rackets since 1917 was fully in the composite world for its high-end line. Developed as one of the first carbon tennis rackets, the Pro Staff line was actually our third venture into the carbon tennis racket space, following our “Galaxy” and “Sting” racket lines. In fact, when Pro Staff first debuted in 1983, we were selling wood, steel, and carbon tennis rackets. However, Pro Staff’s unique carbon and aramid fibers double braid instantly garnered the attention of serious players due to its combination of power, feel, and control. It’s safe to say that the success of this original Pro Staff line ensured carbon would be the premier material used in performance tennis rackets going forward.

Composite fiber has remained the key material now for over 30 years. With about five major manufacturers of the graphite material, every racket maker has their own tweak on the system, trying to bring out different attributes of the fiber, sometimes mixing and matching differing fiber types and resins within single rackets.

Source: Article "The history of rackets and why players experiment with head size, materials", written by Tim Newcomb.

Source:#thenativelab