📢Saturday Spotlight!📢 DYNAPIXEL tool!

Cikoni is trying to solve a recurrent problem in the composites industry: the high costs of the tools and molds that are necessary for every fiber composite manufacturing technology and for every new geometry to be built.

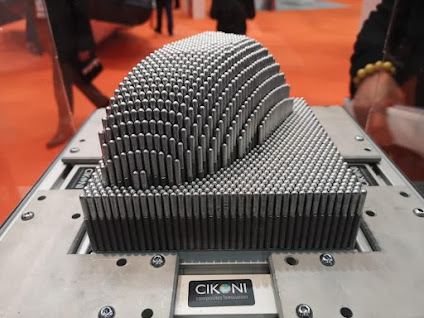

This is where the reconfigurable DYNAPIXEL tool system comes in. By means of a discretization of the tool surface with actuated pins, rapid prototypes or customer-specific components can be created without recurring tooling costs. An elementary constituent for the efficient use of the tool is a closed digital process chain. The DYNAPIXEL software uses script-based generation of support points directly in CAD and the seamless transfer of this data to the control

software of the DYNAPIXEL tool. This also enables the fast, adaptive production of components.

DYNAPIXEL also uses a silicone membrane, which can be used as a laminating surface and with molding processes up to 180°C. For double-diaphragm forming, you would enter the CAD data, let the software actuate the mold geometry, apply a vacuum to draw down the silicone surface on top, laminate the composite plies, close the matched mold with a second membrane and complete the cure.

Surface finish has not been a driving issue because DYNAPIXEL was developed as a tool to speed R&D. Cikoni's goal was to produce additional molds and design iterations without much additional cost. "Once you freeze the part design, you would then switch to CNC-machined metal molds. You can also use this as a performing tool", says Farbod Nezami, one of CIKONI’s co-founders.

Source: CompositesWorld

#managingcomposites

No comments:

Post a Comment