Today we will dive deeper into the fiberglass world! 🧐

As in a common soda-lime glass, the principal ingredient in all fiberglasses is silica (SiO2). Other oxides, such as B2O3 and Al2O3, are added to modify the network structure of SiO2 as well as to improve its workability. The internal structure of fiberglasses is a three-dimensional, long network of silicon, oxygen, and other atoms arranged randomly.

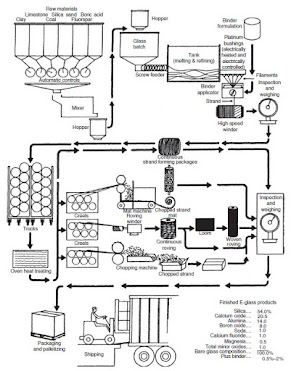

But how is fiberglass manufactured?

It all starts once raw materials are mixed and placed on a glass batch, which has a screw feeder that connects it to the tank, which is heated to melt the glass (>1370°C). The molten glass is fed into electrically heated bushings, which are generally made of platinum or metal alloy, with up to 3,000 very fine orifices. The molten glass passes through the orifices and comes out as fine filaments. Special binders are added and the strands are caught up on a high-speed winder.

The basic continuous commercial fiberglass is a strand. The strands can be turned into many different forms, such as rovings, woven fabrics, pre-impregnated fabrics, chopped strands, or even milled.

Bibliographical Reference:

Fiber Reinforced Composites – Materials, Manufacturing, and Design - Page 61

No comments:

Post a Comment