Today's KNOWLEDGE Share : Hengshen’s carbon fibre materials are used in a 143-meter-long wind turbine

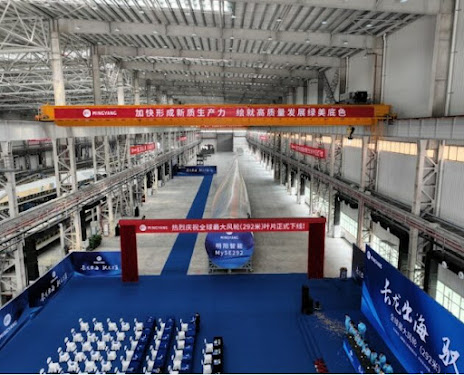

Today's KNOWLEDGE Share Hengshen’s carbon fibre materials are used in a 143-meter-long wind turbine blade.The blade is 143 meters long and has an impeller diameter of 292 meters. It is one of the wind turbine blades with the largest impeller diameter in the world. The carbon fibre fabric used in this blade is exclusively supplied by China’s Hengshen which has annual production capacity of 5,000 tons of carbon fibre. The product portfolio covers raw silk, carbon fibre, sizing agents, fabrics, liquid resins, adhesives, prepregs, carbon fibre composite parts, and aviation composite structural parts. In 2021, Hengshen’s 24K carbon fibre, fabric and carbon plate products obtained DNV certification from the international authoritative certification agency, becoming the first domestic carbon fibre unit to obtain this certification. Up to now, Hengshen has supplied products such as carbon fibre pultruded sheets and warp-knitted fabrics in batches to domestic and foreign wind turbine man