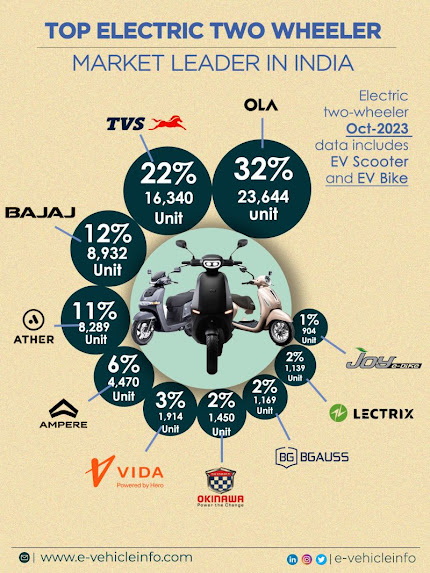

Top Electric Two Wheeler Leader In India

Sales of Electric Two Wheelers surged by a whopping 17% this festive season compared to last month in India The top three companies that did well in October are OLA Electric, TVS Motor, and Bajaj Auto. OLA Electric sold 23,644 vehicles last month, up from 18,615 in September, which is a 27% increase in MOM growth. TVS Motor sold 16,340 vehicles last month, compared to 15,576 in September, showing a 5% MOM growth. As for Bajaj Auto, they sold 8,289 vehicles last month, compared to 7,087 in September, with a MOM growth of 26%. These companies are doing a great job in the electric market. If we crunch the numbers and calculate the monthly growth of the top five companies, they have 82% of the market share of the total sales. Source:Electric Vehicle Info Read complete here: https://lnkd.in/d2fMtT-i Follow: http://polymerguru.blogspot.com