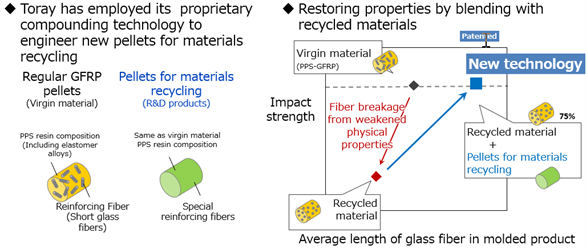

Today's KNOWLEDGE Share:Toray developed Glass fiber reinforced PPS recycling technology

Today's KNOWLEDGE Share Toray Developed Glass Fiber Reinforced PPS Recycling Technology -Established New Technology which matches initial performance with virgin material and reduces CO2 emission - Toray Industries, Inc., announced today that it has developed a technology that makes it possible to recycle glass fiber-reinforced #polyphenylenesulfide (PPS-GFRP) whose performance matches initial performance of virgin resins. By Increasing recycling ratio of PPS GFRP, it will contribute to reducing #CO2emission . PPS resin is an #engineering plastic with excellent #heatresistance and chemical resistance. More than 90% of PPS resin is glass fiber reinforced and applied for various types of industrial applications. Also, PPS resin has excellent insulation resistance. It is applied for #electronicparts such as #semiconductors and #EVparts . Demand of PPS resin is expected to increase along with these applications and the need of PPS recycling reins. The conventional process for re