Today's KNOWLEDGE Share::Repairs for thermoplastic composite aerostructures!

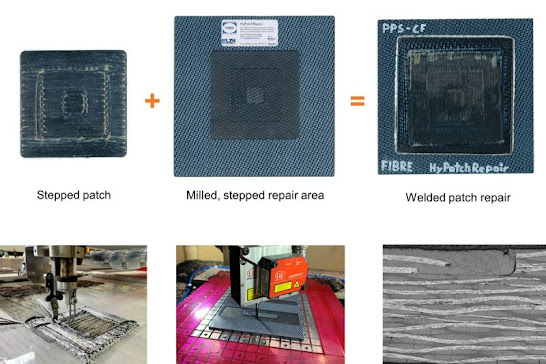

Today's KNOWLEDGE Share Developing repairs for thermoplastic composite aerostructures! The HyPatchRepair project (2019-2022) was funded by the #German government, as part of the LuFo-V3 #aerospace research program, to demonstrate rivet-free repair technology for continuous #fiberreinforced TPC parts. The goal was a set of automated repair techniques to restore the original load-carrying capacity, geometry and aerodynamic surface without adding weight for parts such as #fuselageskins , #wings , #winglets and empennage components, including rudders. These techniques would prepare the repair area, fabricate a load-optimized repair patch and then integrate the patch into the repair area using proven and cost-effective technologies. The German HyPatchRepair consortium was led by research institutes Faserinstitut Bremen and Laser Zentrum Hannover. The project included Airbus Operations, #aircraftrepair services provider Lufthansa Technik , small aircraft manufacturer Silence Aircraf