Today's KNOWLEDGE Share: DMA

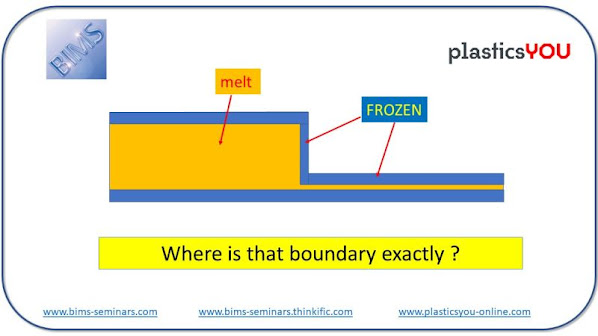

Today's KNOWLEDGE Share: DMA I praised the incredible power of Dynamic Rheology to study polymer flow behaviour and the polymer molecular structure. To be totally fair, I have to also acknowledge the equally valuable power of Dynamic Mechanical Analysis (DMA or DMTA). The principle is strictly the same, with an in-phase and out of phase response. The test is however conducted on solid samples (tension, torsion, bending...) and is most useful in a Temperature sweep approach, ideally from cryogenic temperatures up and above Tg. The data produced (in addition to the Tg value) can help assess the damping characteristics of the polymer for NVH aspects for instance. The observation of multiple sub-Tg transitions is of great spectroscopic interest to understand molecular motions and segmental movements. These transitions are the key reason for toughness observed below Tg in many polymers, a performance aspect we rely upon everyday in our plastic parts. Subtle plasticizing or anti-plastici