Today's KNOWLEDGE Share:

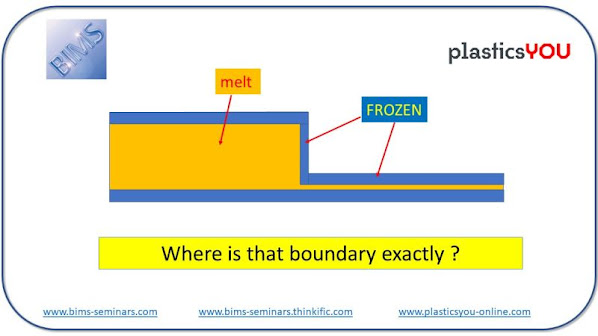

When trying to model Injection Molding one has to determine the transient frozen layer thickness.And it is more tricky than most might think.

For amorphous polymers the best transition temperature would be available straight from the PvT data and will even include the important pressure dependence. It will however not include any cooling rate dependence and Tg is extremely sensitive to cooling rate, as people observe daily with DSC

PvT is essentially measured in a quiescent state close to thermodynamic equilibrium (very slow heat/cool rates).

For semi-crystalline materials the problem is worse. We need to capture the crystallization temperature which is pressure dependent also (that can be seen in PvT) but extremely dependent on cooling rate (crystallization kinetics aspects).

Furthermore, the strong nucleation effect of shear-stress close to the outer layers will dramatically increase, locally, this transition temperature. Which means the transition temperature will be very different from skin to core.

In essence, there is not such a thing as ONE no flow temperature or transition temperature.

To preserve mass balance in molding simulation it will also be of key importance to perfectly "sync" the phase change for all physical properties (PvT, thermal data, viscosity,...).

We still have a long way to go to fully capture this complex physics in our beloved commercial software tools.The best attempt I know of, was an old Research Release version of Moldflow, work I was involved in) including explicit crystallization kinetics and implementing "dynamic" PvT (transition zone driven by real kinetics), with full sync of all other variables.

Source:VITO LEO

Visit MY BLOG https://lnkd.in/fcSeK9e

#polymers #plasticsengineering #injectionmolding #temperature #moldflow #frozen

No comments:

Post a Comment