Today's KNOWLEDGE Share:Composite helmet

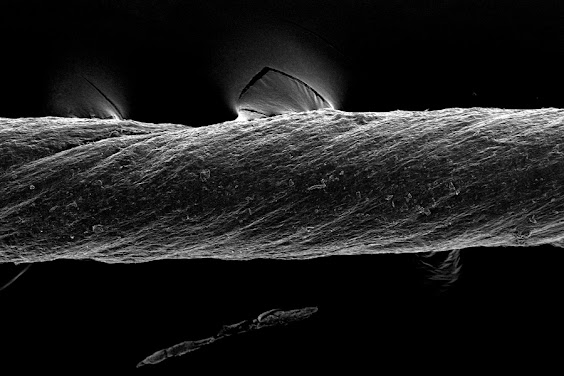

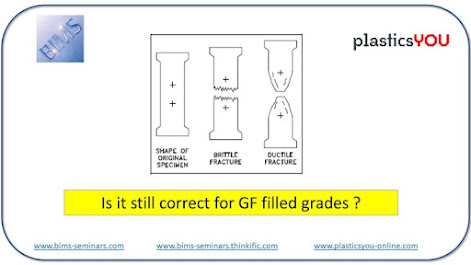

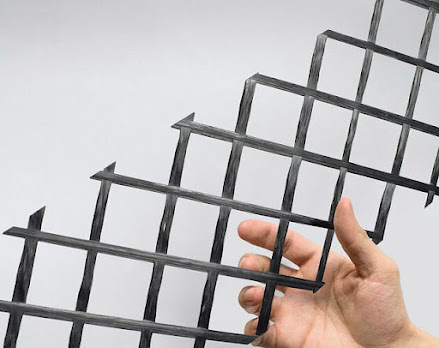

Today's KNOWLEDGE Share: Composite helmet ALUULA Composites, an advanced materials technology firm, has collaborated with mountain sports brand Black Diamond Equipment to develop ultralight and strong composite materials for use in the next generation of Black Diamond’s pinnacle climbing helmet, the 2023 Vapor! Aluula developed a custom penetration shield. The crown of the Black Diamond helmet uses Aluula Gold composite material. Aluula composites combine thin polymer films with ultrahigh molecular weight polyethylene (UHMWPE) fibers woven in various configurations (e.g., 0/90° and bias fabrics) to meet the technical requirements of different applications! Aluula’s material is said to have a 44% higher strength-to-weight ratio than previously used Kevlar (aramid) and reduced the weight of the helmet’s penetration shield by 40%; the new version of the Vapor weights in at 155 grams in total (compared to the previous model at 186 grams), ensuring that climbers never compromise perfo