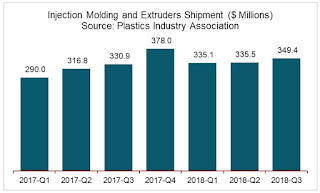

Plastics Machinery Shipments Continued to Increase in Q3 of 2018 in North America

The plastics machinery shipments in North America continued to increase in the third quarter according to the statistics compiled and reported by the Plastics Industry Association’s (PLASTICS) Committee on Equipment Statistics (CES). Injection Molding & Extrusion Machinery Shipment The preliminary estimate of shipments of primary plastics equipment (injection molding and extrusion) for reporting companies totaled $349.4 million in the third quarter. This was a 4.1-percent increase from the $335.5 million (revised) second-quarter shipment. Injection molding shipments in the second quarter were higher than previously thought. Year over year, shipments grew 5.6 percent. Perc Pineda PhD, Chief Economist of PLASTICS, said: “Plastics machinery shipments recovered in the third quarter following a weak second quarter. We expect higher shipments in the fourth quarter. We have a tight labor market and U.S. manufacturers, including plastics machinery manufactu