Toho Tenax Incorporates Carbon Fiber & CNT for New Shock-resistant Hybrid Prepreg

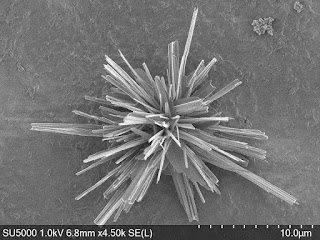

Toho Tenax has announced that it has developed a new high-tensile, highly shock-resistant prepreg that incorporates carbon fiber developed by Toho Tenax for aerospace applications and specialized carbon nanotubes (CNT). Intermediate Material for Carbon Fiber Reinforced Plastics A prepreg is a carbon fiber sheet pre-impregnated with matrix resin and used as an intermediate material for carbon fiber reinforced plastics (CFRP). Toho Tenax’s new hybrid prepreg has been adopted by Mizuno Corporation in a new golf club shaft that weighs nearly 30% less than conventional shafts of the same thickness. The high-tensile prepreg enables the shaft to bend suitably as the ball is impacted and then cuts the shock of impact by more than 10% to reduce club movement on the follow-through swing. The surface of the CNT is specially treated and its structural elements disperse equally when Toho Tenax’s carbon fiber is impregnated with matrix resin containing the CNT. T