SABIC announced that its #STAMAX™ 30YH570 resin has earned the UL Verified Mark from Underwriters Laboratories.

This 30% #glass fiber-reinforced copolymer resin, a featured product offered under the company’s BLUEHERO™ electrification initiative, is the first polymer used in electric vehicle (EV) battery systems to receive UL Verification for marketing claims of thermal and mechanical performance.

UL Verification, based on an objective, scientific assessment by a respected third party, can give customers high confidence in the flame delay performance of this product.

Milestone in Evolving EV Battery Systems:

The vast majority of EV batteries perform without issues throughout their useful life. Although thermal runaway incidents are extremely infrequent, the safety-conscious automotive industry is highly focused on ensuring that the design and performance of EV battery systems prolong the time available to exit a vehicle by delaying the propagation of a fire beyond the battery pack for as long as possible.

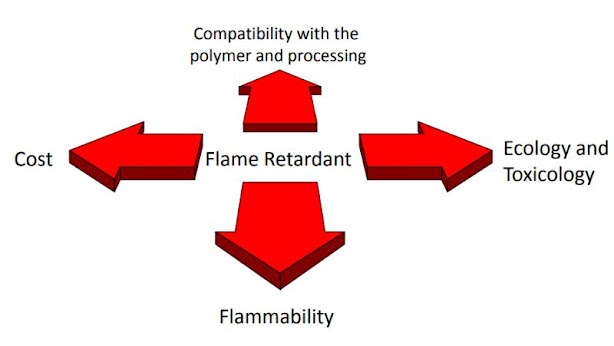

A key consideration is the proper selection and deployment of fire protection materials used for battery pack components, including enclosures and covers, trays, thermal barriers that separate cells into groups, etc.

According to Venkatakrishnan Umamaheswaran (UV), SABIC’s global Automotive marketing director, “UL Verification for the thermal runaway protection of STAMAX™ 30YH570 resin is a significant milestone in our development of polymer materials for today’s rapidly evolving #EVbattery systems. This recognition not only underscores the exceptional performance and safety features of our polymer, but also reinforces the importance of our BLUEHERO™ initiative. By providing cost-effective, lightweight plastic solutions, SABIC is helping to advance EV technology.”

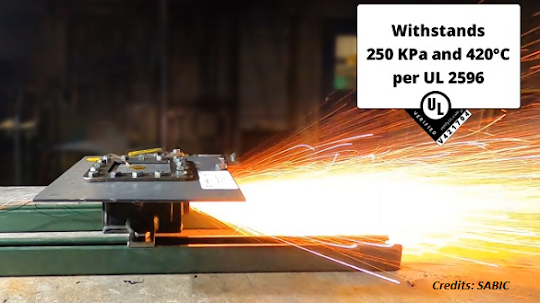

Thermoplastics Over Outdated Steel

Thermal runaway box testing according to #UL 2596, Test Method for Thermal and Mechanical Performance of #BatteryEnclosure Materials, demonstrated that STAMAX™ 30YH570 resin withstood an internal box pressure of 250 kPa and an internal box temperature of 420°C. Results were based on three replicate tests, with a panel thickness of 4mm. The SABIC material features an intumescent capability that helps with fire suppression. Its other key properties include high stiffness and strength and easy processing.

This UL Verification serves as further validation of #SABIC’s continued progress under its BLUEHERO™ initiative in demonstrating the performance advantages of #thermoplastics over outdated steel and other metals for #batterypacks. These benefits include weight and cost reduction, increased functional integration, and enhanced electrical and thermal insulation.

Source: SABIC/Omnexus-specialchem

Follow: http://polymerguru.blogspot.com