Researchers have demonstrated for the first time that high-performance carbon nanotube sheets and textiles can be recycled at the macroscopic scale with nearly 100% retention of mechanical and electrical properties.

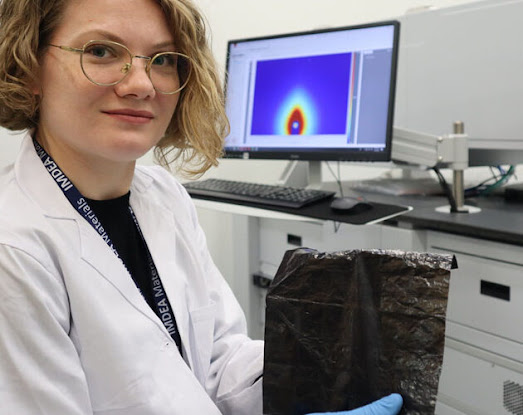

Researchers from IMDEA Materials Institute have published groundbreaking work demonstrating, for the first time, the ability to recycle high-performance carbon nanotube (CNT) sheets while preserving their shape, structural alignment, mechanical and electrical properties, and intrinsic flexibility.

The paper, Network structure enabling re-use and near full property retention in CNT sheets recycled from thermoset composites, was recently published in a special issue of prestigious journal Carbon.

It represents a significant advance in the field of sustainable nanostructured materials and in the viability of fibres, sheets, and textiles made of carbon nanotubes to play a key role in the future green energy transition.

“This research represents a crucial step towards manufacturing and usage of sustainable and recyclable CNT fibres and sheets,” explained Dr. Anastasiia Mikhalchan, Senior Research Associate at IMDEA Materials and Co-PI of the project.

“These will be able to displace widespread CO2-intensive materials, such as conventional carbon fibres and some metals like copper, decreasing our future CO2 emissions footprint”.

“Our work demonstrates that high-performance materials made from carbon nanotubes are recyclable and can be reused in the same application as structural reinforcement or electrical conductors. This is due to the fact that neither their continuity, alignment and mechanical properties nor their conductivity is affected by recycling”.

The work utilizes carbon nanotubes that are rapidly grown and directly assembled into freestanding network materials by means of floating catalyst chemical vapour deposition (FCCVD) synthesis process.

IMDEA Materials Institute is one of the world leaders in the field and is currently the only research centre in the European Union capable of synthesising high-quality nanotube macromaterials.

These CNT fibres and sheets possess high structural toughness and flexibility as well as high mechanical, electrical and thermal properties. This enables their usage in structural reinforcement in composite laminates, as well as printable strain/stress sensors, electrical conductors, and flexible battery anodes, among other applications.

In addition to the demonstrated recyclability in the macroscopic sheet-format, the researchers envision the future possibility of next-level disintegration of the recycled sheets to their building blocks – CNTs – in liquid crystalline solutions, which could then be re-spun into a new high-quality fibre.

“This prospective is similar to breaking down a LEGO model into its individual bricks, and then re-building the original model with the same shape, robustness, and quality,” explained Dr. Mikhalchan.

“This is never possible with conventional carbon fibres because their crystalline structure is formed by fused crystallites in the graphitisation process, so they cannot be “broken down” into individual crystallites and re-graphitized again into a continuous fibre filament”.

“In contrast, carbon nanotubes are capable of dissolution in superacids and can be re-spun into a fibre, which is a matter of future confirmation”.

This pioneering work is supported by the Rice University-led Carbon Hub Initiative. IMDEA Materials’ Multifunctional Nanocomposite research group, led by Dr Juan J. Vilatela, is an active member of the initiative, alongside some of the world’s most prestigious research institutions such as the University of Cambridge, Stanford University, Georgia Tech, and MIT.

Carbon Hub is targeting a zero emission future, and together with the stakeholders from the oil&gas industry, pursue the new paradigm of sustainable co-production of clean hydrogen and advanced carbon nanostructured materials from natural gas and oil.

Instead of burning hydrocarbons to generate energy while releasing gigatons of CO2 into the atmosphere, the Initiative proposes the innovative transformation of hydrocarbons into high-performance value added nanocarbons (such as CNT fibres and sheets) with cogenerating net clean energy as (turquoise) hydrogen.

Presently, the world’s CNT production capacity is in the order of 10 kt/year, a rate which is increasing at roughly 30% annually. However, this could accelerate to the megatone scale if the Carbon Hub efforts are successful and nanocarbons start displacing metals.

The work demonstrated by IMDEA Materials researchers is another milestone in this trajectory, confirming that value-added carbon nanotube materials are, by their nature, recyclable and can be re-used in the same application.

Their network structure and inherent toughness, similar to ductile polymers, makes them extremely tolerant to defects and therefore suitable for re-use and re-processing as high added value materials.

“Even three years ago, there was little interest in recycling CNT-based materials, but now it is becoming a far more relevant topic”, Dr. Mikhalchan stated. “We believe our research will stimulate the scale-up of manufacturing high-performance CNT materials and their faster adoption by industry, knowing that such materials offer sustainability and recyclability and are capable of reducing component weight and industry’s CO2 footprint”.

Those behind the recent breakthrough, alongside Dr. Mikhalchan, include former IMDEA Materials intern Sergio Ramos Lozano, IMDEA Materials PhD student Dr. Andrea Fernández Gorgojo, Prof. Carlos González and Dr. Vilatela.

source:www.materials.imdea.org/jeccomposites.com