Today's KNOWLEDGE Share:

Petrochemicals Historical Timeline 4

1930s New process of alkanisation and fine powder fluid-bed production increases the octane rating of aviation gasoline.

1931 Neoprene invented by DuPont scientists after attending a lecture by Belgian priest and chemistry professor Dr Julius Nieuwland.

1931 German organic chemist Friedrich Bergius and Carl Bosch share a Nobel Prize for their work in high-pressure hydrogenation.

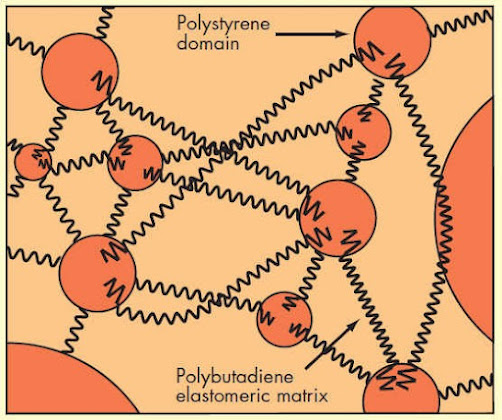

1933 German scientists invent Buna-S, a synthetic rubber made from styrene and butadiene.Mainly used for car tyres.

1933-1935 Plexiglass was discovered by accident by German researcher Otto Röhm. He developed a method for polymerising methyl methacrylate

which was intended for use as a drying oil in varnishes but found it could also be used as a coating for safety glass. Plexiglass was manufactured from 1938, used in war planes from 1940 and in car exteriors from 1974.

1933 A white, waxy material, is discovered by accident by two organic chemists at the UK’s Imperial Chemical Industries (ICI) research laboratory. ICI chemist Michael Perrin developed a high-pressure synthesis process in 1935 to turn the waxy material into polyethylene. It was available on the mass market in the toy sector from the 1950s.

1935 American chemist Wallace Hume Caothers created a fibre which came to be known as Nylon.Nylon stockings were introduced to the US market in 1940 to great acclaim. The material is used today for multiple purposes including fabrics, carpets, ropes and guitar strings. Solid nylon is used for mechanical parts.

1936 Catalytic cracking, using silica and alumina-based catalysts, introduced by French scientist Eugene Houdry

(to be continued)

Source:WPC Guide

Visit MY BLOG http://polymerguru.blogspot.com

#petrochemicals #nylon #plastics #polymerscience #neoprene #butadiene #polyethylene #development #alumina #mma #bosch