Today's KNOWLEDGE Share:

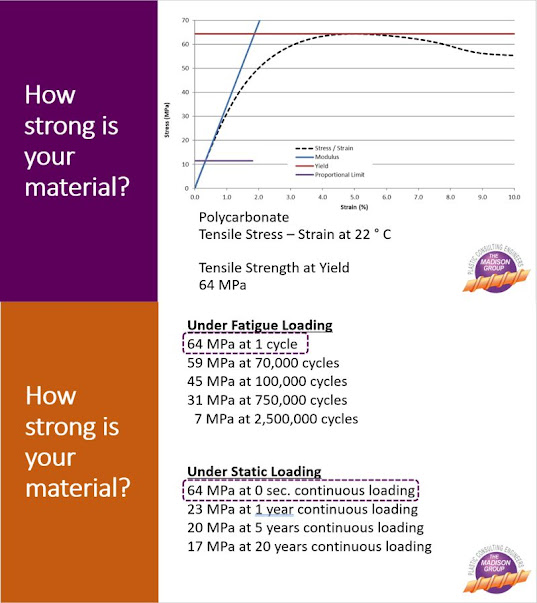

How Strong is Your Material?

Do you know the true strength of your material? With plastics, that is a trick question.

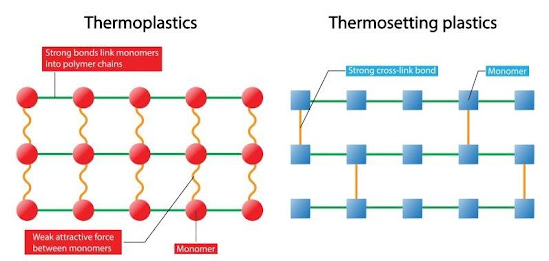

Because of their molecular structure, thermoplastic materials have different properties compared to other materials, like metals.

· The polymer molecules consist of very long chains – high molecular weight.

· The individual polymer chains are entangled in each other.

· The polymer chains are mobile and can slide past each other because they do not share chemical bonds with the other chains around them.

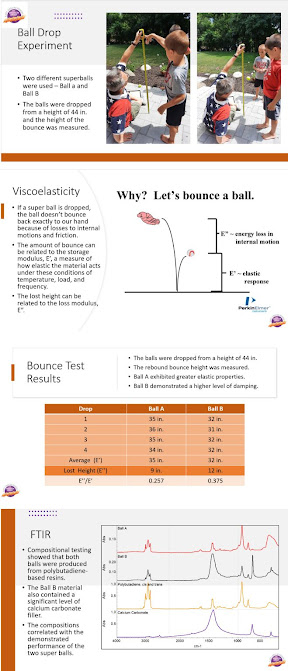

Because of this, plastics exhibit viscoelastic behavior, displaying aspects of both elastic and viscous performance. Attributed to their viscoelastic character, the properties of plastics, including tensile strength, will vary depending on the conditions of the stress loading. This means the “strength” of the material will vary over temperature, time under load, duration of dynamic loading, strain rate, and more.

Unfortunately, this is not captured on plastic material datasheets. For a particular grade of polycarbonate, the tensile strength as determined by standard tensile testing was determined to be 64 MPa, a good match with the datasheet value. However, this is not how the component manufactured from the polycarbonate will be stressed – it is expected to last longer in field use than the 90 seconds it took for the tensile test, and it will be under continuous static loading or dynamic loading depending on the specific application. Based upon realistic conditions, creep and fatigue tests were performed. The testing determined that the actual material strength was 20 MPa for 5 years under continuous loading and 31 MPa at 750,000 cycles, the expected service life. Obviously these are far less than the 64 MPa identified as the tensile strength.

Source:The Madison Group

Visit MY BLOG http://polymerguru.blogspot.com

#plastics #plasticsengineering #polycarbonate #failure #engineering #design #failureanalysis #fatigue #stess #creep #tensile #loading