Today's KNOWLEDGE Share:

Viscoelasticity

I am always looking for new ways to understand the viscoelastic properties of polymeric materials. I found an interesting explanation in the brochure, “Dynamic Mechanical Analysis Basics”, from PerkinElmer, Inc. It was focused on understanding the concepts of viscoelasticity as related to storage modulus, E’; loss modulus, E”; and the tan of the phase angle known as damping, the ratio of the loss modulus to the storage modulus, Damping = tan δ = E”/E’.

These can be difficult concepts to comprehend. One place to start is Young’s modulus. Young's modulus, E, is the modulus of elasticity, a mechanical property that describes the stiffness of a solid material when the force is applied lengthwise. It quantifies the relationship between stress (σ) and axial strain (ε) in the linear elastic region of a material, E= σ/ε. This is a basic concept, but polymeric materials are viscoelastic and non-linear, and their behavior requires further explanation.

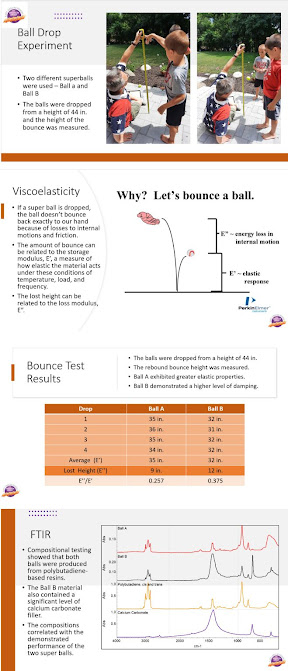

The PerkinElmer explanation used an elastic superball. If we drop a super ball, the ball doesn’t bounce back exactly to our hand because of losses to internal motion and friction. The amount of bounce can be related to the storage modulus, E’, a measure of how elastic the material acts under these conditions of temperature, load, and frequency. The lost height can be related to the loss modulus, E”.

We conducted this superball drop experiment on two different balls. The superballs were dropped from a height of 44 in. and the rebound was measured. The results, shown in the table below, revealed a difference between the two superballs. Ball A produced more rebound, with a higher bounce back, compared with Ball B. This indicated that Ball A had a greater elastic response with less loss and less damping compared with Ball B. The bounce test illustrated a clear performance difference between the two balls.

The variation in the properties of the two superballs was explained by compositional differences between the two materials. The balls were analyzed using Fourier transform infrared spectroscopy (FTIR). Both balls were produced from polybutadiene-based resins. However, the Ball B material also includes a significant level of calcium carbonate. This filler accounted for the lower elastic response / greater loss in the Ball B performance. The next logical step would be to quantify the filler loading through thermogravimetric analysis.

There is a more formal way to measure the storage modulus, loss modulus, and damping or tan δ. Dynamic mechanical analysis (DMA) can effectively assess these important characteristics of polymeric materials.

Source:The Madison Group

Visit MY BLOG http://polymerguru.blogspot.com

#plastics #rubber #elastomers #ftir #mechanical #viscoelasticity #modulus