Overcoming the conventional:

Launched in 2015, HORIZN STUDIOS was Europe’s first direct-to-consumer travel brand. Focused on innovative design, convenience, and sustainable solutions, it was the first company in the world to release luggage with a removable charging function.

In 2021, however, HORIZN STUDIOS was looking to really revolutionise luggage design. Despite the challenges of the global pandemic, the company intended to create the world’s most sustainable luxury luggage. Embracing a philosophy of lightweight, high-performance, and sustainable materials, HORIZN STUDIOS sought out a partner that would be able to simultaneously fulfil these demanding criteria.

Natural fibre composite technologies

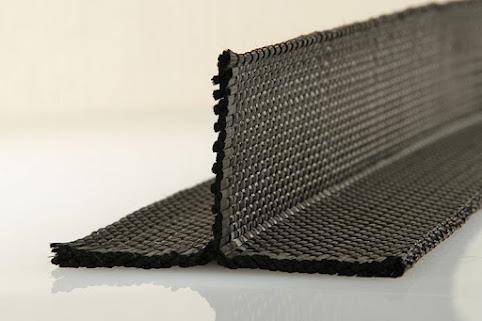

Already proven in the unrelenting world of motorsport and the equally challenging arena of ultra-high-end furniture, Bcomp’s innovative ampliTex™ and powerRibs™ are ground-breaking carbon-neutral composite reinforcements made entirely from flax fibre.

Cultivated across Europe, flax is an indigenous plant that has been part of the agricultural industry for centuries. With low water and nutrient requirements and little need for pesticides and fertilisers, it is a popular rotational crop with excellent utility – useful for feed, making flax oil, and its fibres can be used in textiles.

ampliTex™ and powerRibs™ make the most of flax’s inherent mechanical properties, creating composite parts with high stiffness, resistance to breakage, torsion, and compression – perfect to form the shell of tough and sturdy luggage. Using appropriate care and processes, Bcomp’s materials also offer a flawless surface finish, suitable for luxury product applications.

Most importantly, ampliTex™ and powerRibs™ are some of the most sustainable composite technologies available today, particularly in the high-performance category. Analysis of past projects has shown that Bcomp’s technologies can provide a material emission reduction of 90% when compared to its most commonly used equivalent, carbon fibre. Overall, they offer an outstanding 80-85% cradle-to-gate emission reduction, while retaining many of the performance benefits.

Unlike other luggage materials that would be sent to landfill at the end of their useful life, the Circle One range has various end-of-life recycling options thanks to Bcomp’s flax fibre composite technologies. ampliTex™ also opens up the possibility of repair, rather than replace, something of great interest to the HORIZN STUDIOS team.

Source:bcomp.ch/JECCOMPOSITES