The world's most valuable chemical brands on the 2022 list are revealed!

Sunday, June 5, 2022

Saturday, June 4, 2022

Team Effort

Teamwork is the ability to work together toward a common vision. The ability to direct individual accomplishments toward organizational objectives. It is the fuel that allows common people to attain uncommon results.

Visit MY BLOG https://lnkd.in/fcSeK9e

Friday, June 3, 2022

Car tyres produce vastly more particle pollution than exhausts, tests show

Almost 2,000 times more particle pollution is produced by tyre wear than is pumped out of the exhausts of modern cars, tests have shown.

The tyre particles pollute the air, water and soil and contain a wide range of toxic organic compounds, including known carcinogens, the analysts say, suggesting tyre pollution could rapidly become a major issue for regulators.

Air pollution causes millions of early deaths a year globally. The requirement for better filters has meant particle emissions from tailpipes in developed countries are now much lower in new cars, with those in Europe far below the legal limit. However, the increasing weight of cars means more particles are being thrown off by tyres as they wear on the road.

The tests also revealed that tyres produce more than 1tn ultrafine particles for each kilometre driven, meaning particles smaller than 23 nanometres. These are also emitted from exhausts and are of special concern to health, as their size means they can enter organs via the bloodstream. Particles below 23nm are hard to measure and are not currently regulated in either the EU or US.

“Tyres are rapidly eclipsing the tailpipe as a major source of emissions from vehicles,” said Nick Molden, at Emissions Analytics, the leading independent emissions testing company that did the research. “Tailpipes are now so clean for pollutants that, if you were starting out afresh, you wouldn’t even bother regulating them.”

Molden said an initial estimate of tyre particle emissions prompted the new work. “We came to a bewildering amount of material being released into the environment – 300,000 tonnes of tyre rubber in the UK and US, just from cars and vans every year.”

There are currently no regulations on the wear rate of tyres and little regulation on the chemicals they contain. Emissions Analytics has now determined the chemicals present in 250 different types of tyres, which are usually made from synthetic rubber, derived from crude oil. “There are hundreds and hundreds of chemicals, many of which are carcinogenic,” Molden said. “When you multiply it by the total wear rates, you get to some very staggering figures as to what’s being released.”

The wear rate of different tyre brands varied substantially and the toxic chemical content varied, even more, he said, showing low-cost changes were feasible to cut their environmental impact.

“You could do a lot by eliminating the most toxic tyres,” he said. “It’s not about stopping people driving, or having to invent completely different new tyres. If you could eliminate the worst half, and maybe bring them in line with the best in class, you can make a massive difference. But at the moment, there’s no regulatory tool, there’s no surveillance.”

The tests of tyre wear were done on 14 different brands using a Mercedes C-Class driven normally on the road, with some tested over their full lifetime. High-precision scales measured the weight lost by the tyres and a sampling system that collects particles behind the tyres while driving assessed the mass, number and size of particles, down to 6nm. The real-world exhaust emissions were measured across four petrol SUVs, the most popular new cars today, using models from 2019 and 2020.

Used tyres produced 36 milligrams of particles each kilometre, 1,850 times higher than the 0.02 mg/km average from the exhausts. A very aggressive – though legal – driving style sent particle emissions soaring, to 5,760 mg/km.

Far more small particles are produced by the tyres than large ones. This means that while the vast majority of the particles by number are small enough to become airborne and contribute to air pollution, these represent only 11% of the particles by weight. Nonetheless, tyres still produce hundreds of times more airborne particles by weight than exhausts.

Source:The Guardian

Thursday, June 2, 2022

The enzyme discovered that breaks down PET in less than a day

German chemists have discovered a highly efficient enzyme that breaks down PET, one of the most used types of plastic in the world, in record time.

Christian Sonnendecker and his colleagues at the University of Leipzig identified the enzyme, along with several others, in a compost pile.

The plastic-eating enzyme could make biological recycling of PET (polyethylene terephthalate) possible much faster than previously thought possible. It was named PHL7.

Bacteria naturally use enzymes to break down plant parts and feed themselves. It has also been known for some time that some enzymes, so-called polyester-cleaving hydrolases, can also degrade plastics. For example, the enzyme LCC, discovered by Japanese researchers, is considered a particularly effective "plastic eater" - there are also fungi that degrade PET.

What distinguishes the new enzyme identified now is its speed of action.

In the experiments, the researchers added PET to containers with an aqueous solution containing the newly identified PHL7 or the well-known LCC, the previous leader in PET decomposition. Then they measured the amount of plastic that had degraded in a given period of time and compared the values to each other.

The result: Within 16 hours, PHL7 caused the PET to decompose by 90%; at the same time, LCC achieved a degradation of only half of that, 45%.

"Therefore, our enzyme is twice as active as the gold standard among the polyester cleavage hydrolases," Sonnendecker stressed. "For example, PHL7 broke a plastic container - the kind used to sell grapes in supermarkets - in less than 24 hours."

The researchers found that a single enzyme building block is responsible for this above-average activity. Where other previously known polyester cleavage hydrolases contain a phenylalanine residue, PHL7 has a leucine.

Biological recycling of PET has advantages over conventional recycling methods, which are primarily based on thermal processes, where plastic waste is melted down for reuse. These processes are highly energy-intensive and the quality of the plastic declines with each recycling cycle.

Enzymes, on the other hand, only require an aqueous environment and a temperature of 65 to 70 degrees Celsius to do their job. Another advantage is that it breaks down PET into its terephthalic acid and ethylene glycol components, which can be reused to produce new PET, without loss of quality, resulting in a closed-loop. So far, however, the biological recycling of PET has only been tested by a pilot plant in France.

The German team is now carrying out experiments for the degradation of PET bottles using the enzyme - compared to fruit and another packaging, typically "crystalline", PET bottles have additives that make their degradation more complicated.

Source:Article: Low Carbon Footprint Recycling of Post-Consumer PET Plastic with a Metagenomic Polyester Hydrolase

Wednesday, June 1, 2022

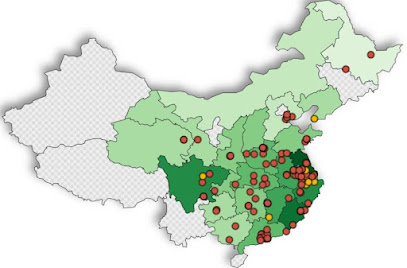

CHINA BATTERY MARKET IN CHINA

According to BMI figures, china is ten times the combined number in Europe and North America. At present 125 batteries, Giga factories are more active in producing batteries. In each province, construction is taking place in China. Most large corporations are eying the Chinese market for investing in various projects.

Source:https://flo.uri.sh/visualisation/8675841/embed

Saturday, May 28, 2022

Global Refinery New and Expansion Projects Outlook to 2026

• 460 upcoming crude oil refinery projects are expected to start operations from 2022 to 2026

• 118 represent new build projects and 342 are expansions of existing projects

• Predictably Asia dominates with the highest capacity additions of 7.3 mmbd by 2026. The Middle East and Africa follow with capacities of 3.8 mmbd and 3.6 mmbd, respectively

• China leads with the highest refinery capacity addition of 3.4 mmbd by 2026. Nigeria and India follow with capacities of 1.7 mmbd and 1.6 mmbd, respectively

• The Lagos I project in Nigeria with a capacity of 650 thousand barrels per day (mbd) leads in terms of refinery capacity.

Visit MY BLOG http://polymerguru.blogspot.com

Cycling forward with bike frame materials and processes!

📢Saturday Spotlight!📢 Cycling forward with bike frame materials and processes!

"Are carbon fiber-reinforced polymer (CFRP) bicycle frames poised for a “great reshoring” — the return of production to locales near the customer base — or will they continue to be fabricated and shipped largely from Asian countries, as the vast majority are today? The short answer, according to bike manufacturers interviewed by CW, is that Asia will continue to predominate. Still, noteworthy changes to the bicycle manufacturing landscape are evident."

"CFRP frame manufacturing is making inroads in North America and Europe, where most CFRP bike enthusiasts reside. “One of the biggest differences [between offshore and reshored manufacturing] is product ownership,” emphasizes Dave Luyckx, chief product officer at Leuven, Belgium-based Rein4ced. “Asia doesn’t have a bicycle culture, but we have this cycling culture that infuses passion into the product.”

"Of course, cycling passion must be accompanied by composites know-how and innovative approaches before reshored CFRP frames achieve considerable market penetration. To the extent that the geography and technology of CFRP bike frame manufacturing are changing, key factors include the same market forces affecting all globalized manufacturing industries today: supply chain issues, the fallout from the pandemic, and geopolitical uncertainties. But the primary agent of change appears to be the classic tension between two manufacturing dynamics often at odds with each other: economies of scale versus production agility. The latter has prompted innovation that includes technical advances in the traditional hand-laid fabrication approach as well as forays into new materials and automated processes."

Want to learn more about this topic? Check out the full article by using this link 👉 https://lnkd.in/ggkPTjjw

Source:#managingcomposites

Today's KNOWLEDGE Share : Safety Meets Performance: Discover Microtex Composites's Flame Retardant Epoxy Prepregs

Today's KNOWLEDGE Share Safety Meets Performance: Discover Microtex Composites's Flame Retardant Epoxy Prepregs 🔥 In industries wh...

-

Envalior launches new PPS compounding facility in Uerdingen, Germany. New facility supports growing demand for Xytron™ in Europe and the Ame...

-

Today's KNOWLEDGE Share What Is Going Wrong in UK Plastics Recycling? Biffa shut its Sunderland plant. Viridor walked away from Avonmout...

-

Today's KNOWLEDGE Share “Robotic 3D printing can compete with traditional boatbuilding”, Simone Barbera and Mattia De Santis, Caracol V...