📢Time to Get Technical...📢

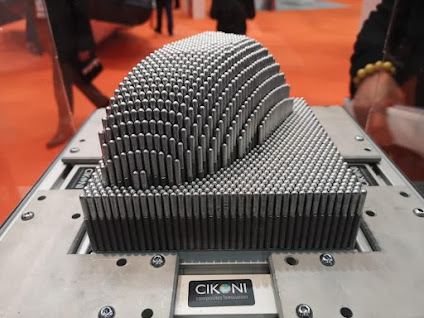

Tailored Fiber Plaplacement cement (TFP) is an embroidery-based tow-steering process that enables complete control over fiber and directionality in a composite preform. During the process, continuous tow is stitched to a backing material using numerical control. The result is highly engineered composite structures that take full advantage of the anisotropic nature of fiber reinforcement.

Several fibrous materials like carbon, glass, basalt, aramid, natural, thermoplastic, ceramic fibers, or metallic threads can be placed in a near-net shape on a carrier material by TFP. Even the placement of different materials at the same time or one after another can be proceeded by TFP. Especially while using the TFP technology for the placement of carbon rovings to create

preforms for composite parts, a high degree of freedom is an advantage. The rovings can be placed exactly according to the distribution of forces within a structural component. This leads to a higher force absorption with fewer stacked layers. 100% reproducibility speaks for itself and is accomplished by the following:

- Automatic perform production.

- Low mass tolerance.

- High dimensional accuracy.

- Reliable identical laying roving.

This cost-effective process is driven by high stitching speed on one hand and multiple laying heads on a machine. In comparison to other textile technologies, the expensive loss of materials is kept to a minimum because of the near-net-shape production of the product. Accordingly, the problem of waste disposal is very little.

Source: University of Dayton Research Institute and ZSK Technical Embroidery Systems.

#managingcomposites