#science 📢Time to Get Technical...📢

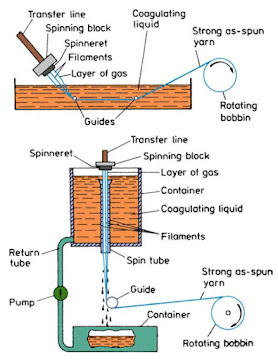

Let's learn more about the dry-jet wet spinning process of producing aramid fibers!

Aramid fiber is a generic term for a class of synthetic organic fibers called aromatic polyamide fibers. The U.S. Federal Trade Commission gives a good definition of an aramid fiber as “a manufactured fiber in which the fiber-forming substance is a long-chain synthetic polyamide in which at least 85% of the amide linkages are attached directly to two aromatic rings.” Well-known commercial names of aramid fibers include Kevlar and Nomex (DuPont) and Twaron (Teijin Aramid).

The basic chemical structure of aramid fibers consists of oriented para-substituted aromatic units, which makes them rigid rodlike polymers. The rigid rodlike structure results in a high glass transition temperature and poor solubility, which makes the fabrication of these polymers, by conventional drawing techniques, difficult. Instead, they are spun from liquid crystalline polymer solutions by dry-jet wet spinning.

The dry-jet wet spinning starts with a solution of polycondensation of diamines and diacid halides at low temperatures (near 0 °C) gives the aramid forming polyamides. Low temperatures are used to inhibit any by-product generation and promote linear polyamide formation. The resulting polymer is pulverized, washed, and dried; mixed with concentrated H2SO4; and extruded through a spinneret at about 100 °C. The jets from the orifices pass through about 1 cm of air layer before entering a cold water (0–4 °C) bath. The fiber solidifies in the air gap, and the acid is removed in the coagulation bath. The spinneret capillary and air gap cause rotation and alignment of the domains, resulting in highly crystalline and oriented as-spun fibers. The air gap also allows the dope to be at a higher temperature than is possible without the air gap. The higher temperature allows a more concentrated spinning solution to be used, and higher spinning rates are possible. Spinning rates of several hundred meters per minute are not unusual. The as-spun aramid fibers are washed in water, wound on a bobbin, and dried. Fiber properties are modified by the use of appropriate solvent additives, by changing the spinning conditions, and by means of some post-spinning heat treatments, if necessary.

Bibliographical Reference:

Composite Materials - Science and Engineering - Page 46

Source:managingcomposites