The chemical compound carbon dioxide knows the general public as a greenhouse gas in the atmosphere and because of its climate-warming effect. However, carbon dioxide can also be a useful source of chemical reactions. A working group of the Karlsruhe Institute of Technology (KIT) in the journal ChemSusChem reports on such an unusual application. It uses carbon dioxide as a starting material to produce the currently very intensively investigated technology material graphene.

Carbon Dioxide - A Useful Source of Chemical Reactions

The burning of fossil fuels such as coal and oil supplies energy for electricity, heat and mobility, but also leads to an increase in the amount of carbon dioxide in the atmosphere and thus to global warming. To cut through this causal chain, scientists are motivated to search for alternative sources of energy, but also alternative uses for carbon dioxide. One possibility could be to see the carbon dioxide as a favorable starting material for the synthesis of recyclables and thus in the economic recovery cycle - possibly even profitable - reintroduce.

An example of this can be found in nature: during photosynthesis in the leaves of plants, biomass is rebuilt from light, water and carbon dioxide and the natural material cycle is closed. In the process, it is the task of the metal-based enzyme RuBisCo to absorb the carbon dioxide from the air and make it usable for further chemical reactions in the plant. Inspired by this metal-based natural transformation, researchers at KIT are now presenting a process in which the greenhouse gas carbon dioxide, together with hydrogen, is directly transferred to the technology material graphene with the aid of specially prepared, catalytically active metal surfaces at temperatures of up to 1000 degrees Celsius.

Graphene

Graphene is the two-dimensional shape of the chemical element carbon, which has interesting electrical properties and is therefore suitable for future, novel electronic components. Its discovery and manipulation in 2004 led to worldwide, intensive research and in 2010 brought the discoverers Andre Geim and Konstanin Novoselov the Nobel Prize in Physics. The two took the graphene by hand from a block of graphite using adhesive tape.

Simple One-step Process

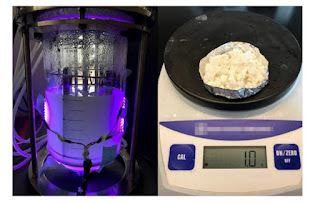

A collaboration of several working groups at KIT is now published in the journal ChemSusChema method to separate graphene by means of a metal catalyst of carbon dioxide and hydrogen. "If the metal surface has the right balance of copper and palladium, the conversion of carbon dioxide to graphene will take place directly in a simple one-step process," said study leader Professor Mario Ruben of the Molecular Materials Working Group at the Institute of Nanotechnology (INT) and at the Institute of Inorganic Chemistry (AOC) of KIT.

In further experiments, the researchers even succeeded in producing the graphene with several layers of thickness, which could be of interest for possible applications in batteries, electronic components or filter materials. The next research objective of the working group is to shape functioning electronic components from the graphene obtained.

Source: Karlsruhe Institute of Technology