📢Time to Get Technical...📢

What are SMC's? How are they manufactured?

Sheet molding compounds (SMC) are high-strength composite materials comprising primarily a thermosetting resin, filler(s), and fiber reinforcement (which is usually chopped). The thermosetting resin is typically based on unsaturated polyester, vinyl ester, phenolic, or a modified vinyl urethane. Typical fillers are calcium carbonate (reduced cost), clay (improved surface), alumina trihydrate (fire retardance), talc (improved temperature resistance), mica (improved weathering), and hollow glass microspheres (weight reduction, thermal insulation).

SMC is a flow molding material and can therefore be used for manufacturing relatively complex-shaped parts, although the level of complexity reduces as the degree of aligned reinforcement is increased.

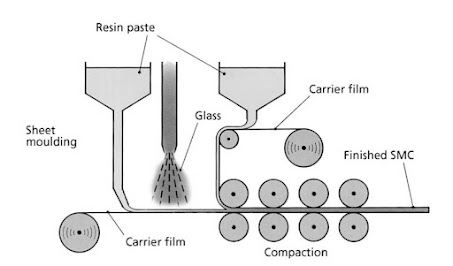

This schematic summarizes how they are manufactured. The manufacturing of SMC’s is a continuous process that starts when a paste is spread uniformly in a carrier film (made of polyethylene or nylon). Then, chopped fibers are randomly deposited onto the paste. The top film is introduced and the sandwich is rolled into a pre-determined thickness.

Bibliographical Reference:

An Introduction to Automotive Composites - Page 116

No comments:

Post a Comment