Porsche’s New Bioconcept-Car Features Natural-fiber Composite Body Parts

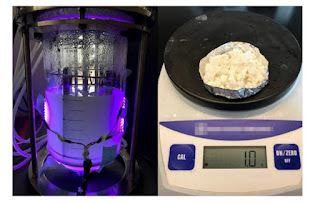

Automaker Porsche launches the new 718 Cayman GT4 Clubsport body parts made of natural-fiber composite materials developed in the Application Center for Wood Fiber Research HOFZET, which is part of the Fraunhofer Institute for Wood Research, Wilhelm-Klauditz-Institut WKI, together with the Institute for Bioplastics and Biocomposites IfBB of Hannover University of Applied Sciences and Arts. Features of Porsche’s New Bioconcept-Car The Bioconcept-Car’s driver and passenger doors and rear wing are made using a mixture of organic fibers. Vegetable fibers as a component in organic composites are a sustainable alternative for lightweight vehicle bodies. The years of experience with the ‘Bioconcept-Car’ were integrated in material development for the parts of the new 718 Cayman GT4 Clubsport, the first car in series production to feature body parts made of a natural-fiber composite material. The driver and passenger doors as well as the rear wing are made using a mixture of organic